When diagnosing a shudder vibration condition on some 2016-2018 Silverado, Sierra; 2016-2020 Tahoe, Suburban, Yukon; 2019-2020 Silverado 1500 and Sierra 1500 models equipped with 5.3L V8 engine (RPO L82, L83, L84) and 6L80 6-speed transmission (RPO MYC), it’s critical to determine the source of the vibration in order to make the proper repairs.

The shudder vibration may be noticed mostly during light throttle acceleration of 30-64 mph (48-104 km/h) during steady state driving with the transmission not actively shifting gears. It also may feel like driving over rough pavement or rumble strips. The shudder feeling may be evident in both Drive and M5 mode.

In general, if there is insufficient engine firing pulse isolation or combustion instability, vibrations can be transmitted through the steering wheel, seat track, or accelerator pedal. A torque converter shudder vibration may be induced by the torque converter clutch in normal driving mode (with an expected TCC slip amount) and is most often due to TCC friction material/ATF degradation). Other sources of a vibration include insufficient damping or isolation of the engine or driveline, an irregular combustion event, and Active Fuel Management (AFM) disturbances.

TIP: DEXRON 6 is the only approved automatic transmission fluid (ATF) to be used with 6L transmissions (RPO MYA, MYB, MYC, MYD) at this time.

Diagnosis with the PicoScope Oscilloscope

Before beginning any repairs, verify and correct any DTCs.

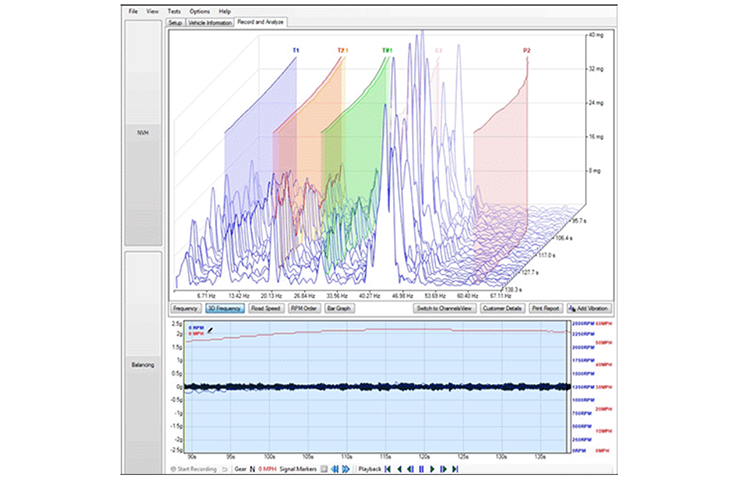

The use of the CH-51450 PicoScope automotive oscilloscope and the CH-51450-A NVH kit can help confirm the disturbance frequency and determine if the disturbance tracks to engine speed (chuggle or misfire), road speed (tire vibration), or remains constant across various inputs (TCC shudder). Place the PicoScope pick-up on a metallic component where vibration can be felt the most (seat track, steering wheel column, accelerator pedal, etc.). Minimize extraneous vibration input by conducting the test on a smooth road and correct any other known vehicle vibration issues (for example, any tire or brake conditions) before testing.

To confirm TCC shudder, the vibration concern must be present in normal operation, but not present with the torque converter clutch disabled or with the torque converter clutch locked. Also perform a TCC slip control test. If TCC shudder is present, a vibration peak will appear at approximately 43Hz +/-3Hz. (Fig. 18) If the vibration frequency follows engine, tire, or driveshaft speed, then it is not a TCC shudder vibration.

Fig. 18

Fig. 18

Diagnosis with GDS2

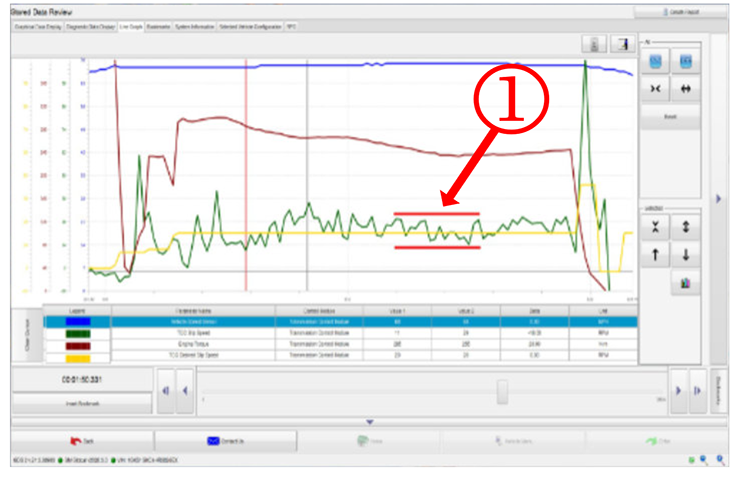

An alternative diagnostic for TCC shudder is to road test the vehicle and monitor commanded and actual TCC slip speeds. Road test the vehicle under light throttle acceleration at 55-65 mph (88-104 km/h) during steady state driving when the transmission is not actively shifting gears and monitor the following GDS2 parameters.

GDS2 data showing TCC slip peak-to-peak below 20 RPM is an example of normal TCC operation. (Fig. 19)

Fig. 19

Fig. 19

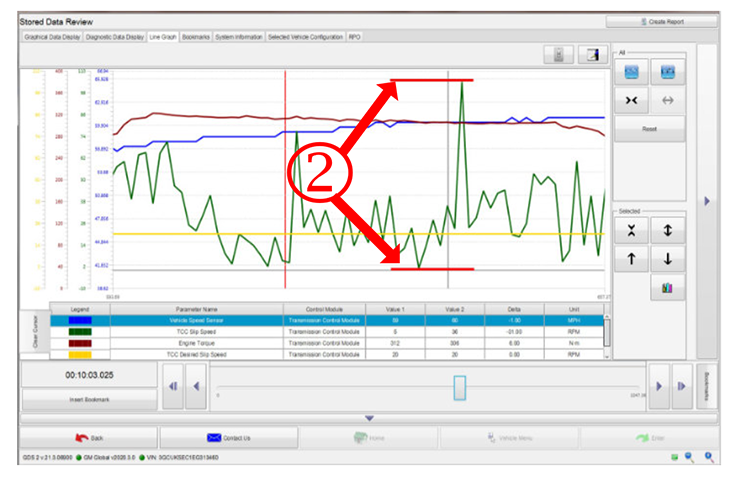

GDS2 data showing TCC slip peak-to-peak erratic near 0 RPM to over 100 RPM in a short time is an example of a damaged torque converter clutch. (Fig. 20)

Fig. 20

Fig. 20

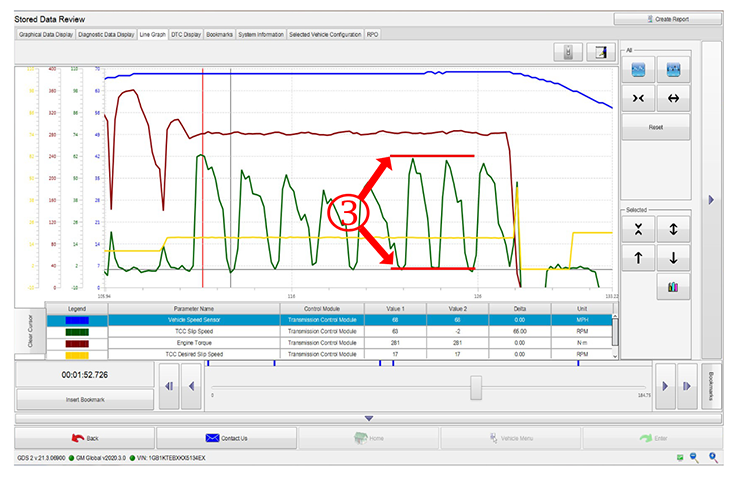

GDS2 data showing TCC slip peak-to-peak repeating near 60 RPM or less is an example of degraded fluid. (Fig. 21) Perform the TCC slip control test within this procedure and compare service tool-collected data results to normal, damaged and degraded operation.

Fig. 21

Fig. 21

Additional information can be found in the latest version of #PIP5504. For more information about diagnosing vibration conditions, refer to Vehicle Vibration Diagnosis in the appropriate Service Information.

– Thanks to Ron Caponey

question on fig 18 is the vibration shown on the blue lines before p2?