GM’s global repair strategy for large wiring harnesses (body, engine, instrument panel, forward lamp, headliner/roof harness, and truck chassis) is to repair/replace the components (cables, terminals, connectors, etc.) instead of replacing the harness. The repair strategy was developed to help reduce repair costs while reducing squeak and rattle conditions.

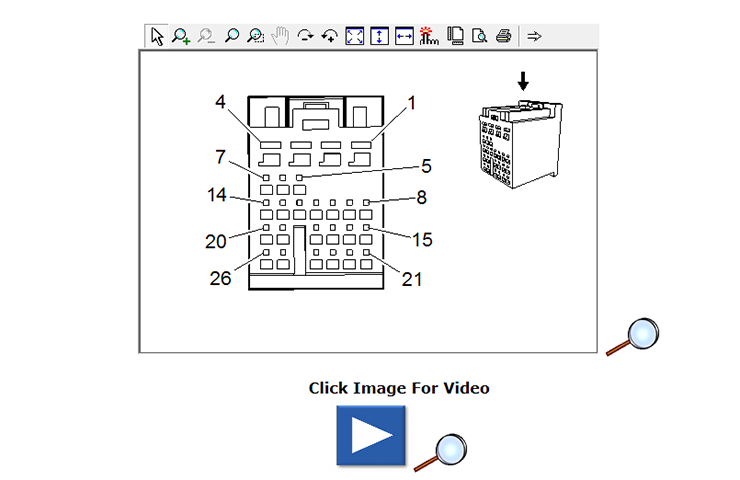

GM Customer Care and Aftersales (CCA) has released all required components to repair these harnesses. For connectors that have 8 cavities or less, a fully populated pigtail with the correct DuraSeal splice is available. For all connectors that have 9 cavities or greater, a connector kit, DuraSeal splices and terminated leads are available. (Fig. 3)

For smaller harnesses (door, seat, steering column, etc.), the repair strategy is to replace the harness.

Fig. 3

Fig. 3

Part Numbers in Service Information (SI)

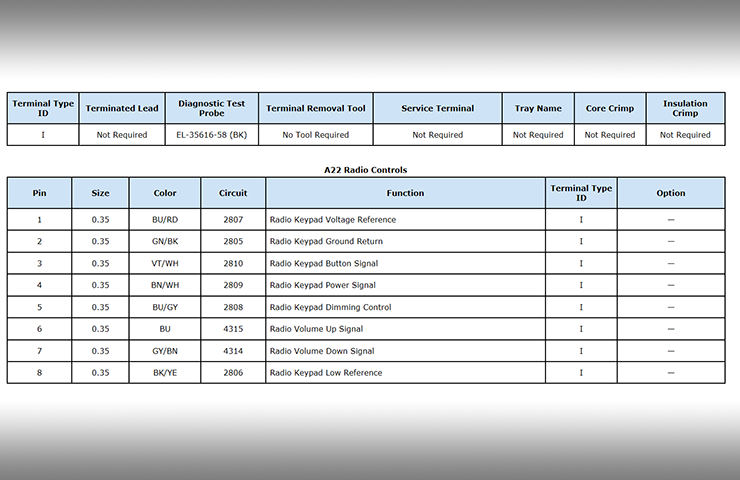

The Connector End View section of the Service Information is the source for part number information. (Fig. 4)

Fig. 4

Fig. 4

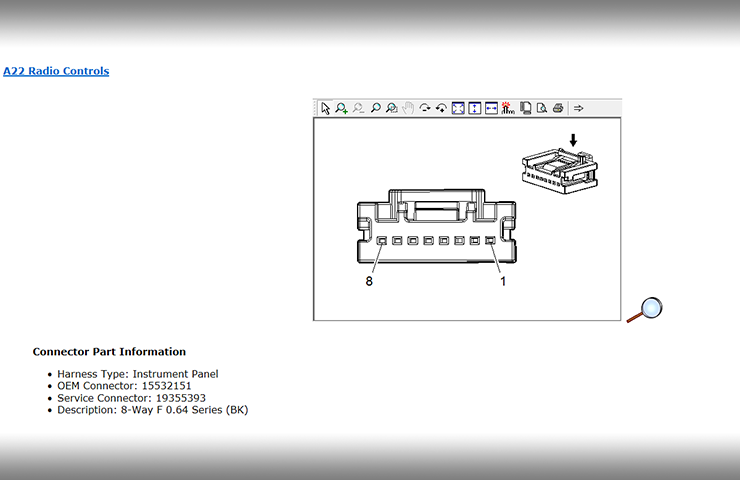

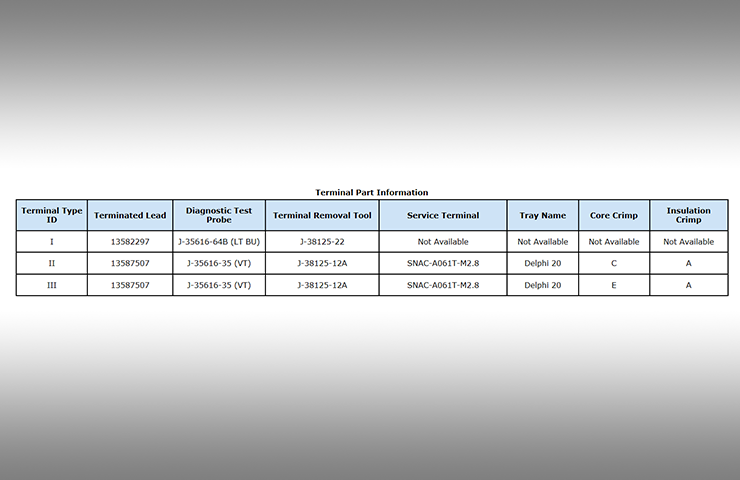

The part information is found just below the connector end view drawing and is presented two ways — the legacy format typically associated with TIFF viewer-supported graphics and the updated format typically associated with CGM viewer-supported graphics. (Fig. 5)

Fig. 5

Fig. 5

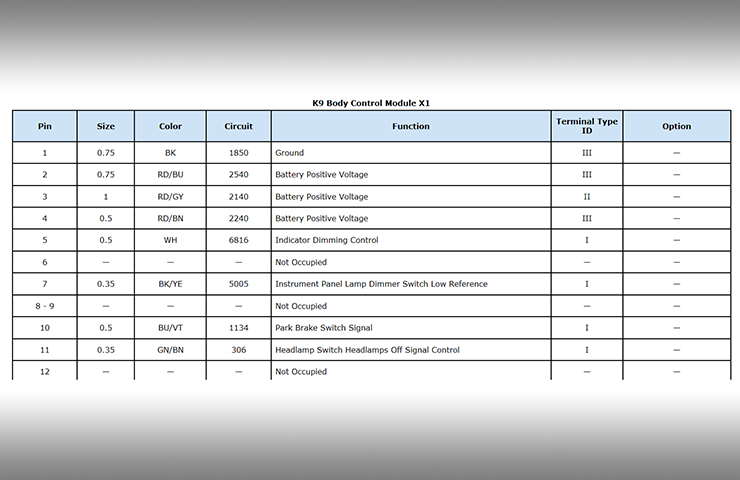

For larger connectors (9 cavities or greater), the Service Information shows the connector kit and the terminated leads. (Figs. 6, 7)

Fig. 6

Fig. 6

Fig. 7

Fig. 7

CCA Engineering has been developing videos to help show how to probe and release terminals for these larger harnesses. See below for an example of a connector video. (Fig. 8) These videos are available in the Service Information.

Fig. 8

Electronic Parts Catalog (EPC) Information

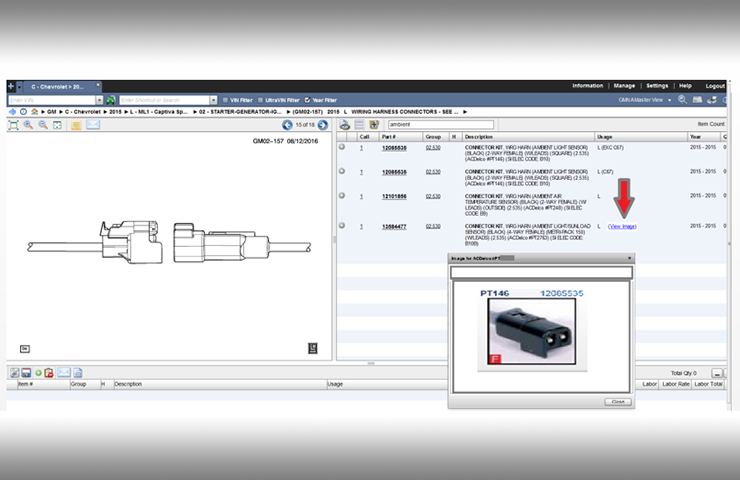

Starting with the 2018 model year, all connector kits, pigtails, and terminated leads are called out by book code and model year in the EPC. Updates to the EPC will allow better searchability for wiring repair components. In addition, pictures are being added to the EPC for these parts to help in ordering the correct wire component. (Fig. 9)

Battery cables, infotainment cables and hoses also are listed in the EPC.

Fig. 9

Fig. 9

TXL Wire

Use TXL wire to maintain factory specifications for wire harness integrity. TXL wire is available through the Customer Care and Aftersales parts catalog within the Chemical Catalog section. In the EPC, find TXL wire in the Chemicals – Fuses – Wire – book section.

For additional information on wiring repairs, refer to Bulletin #13-00-89-008B.

– Thanks to Tammy Burt and Eric Baur

The wire-to-wire harness repair strategy was changed in 2007 to eliminate the use of the terminal trays. This change was implemented due to the cost of the trays by the dealerships, and challenges with having the most current terminals in the trays. There were also cases in the field where vehicles required rework due to the quality of the crimp. The crimp tools used by the technicians can vary and are not validated. Since 2017, the process of releasing the service terminated leads have included obtaining the most robust terminal and largest wire size to be used for service, based on the production connector print. If a service connector, terminated lead or harness is not available to repair a vehicle, a SPAC case is to be created in the system and addressed immediately by the responsible Service Release Engineers.

Please give us all the logistics, and SI support for individual terminal replacement back!!! It’s been too many years since GM took it away. I still dig through the terminal bins to match up terminals I can’t look up.

We know how to crimp terminals properly, it’s not hard.

Terminated leads sometimes don’t even fit, because the wire is the fattest wire that could ever be used in that circuit and won’t go into the connector body half the time.

Pigtails, leads, harness, etc are never in stock anyway.

park assist sensor changed and still not workings