In order to help GM Engineering identify the root cause and troubleshoot some component drains or logic lockups on 2000-2023 GM passenger cars and trucks, it’s critical that power to the module be maintained during shipping; otherwise, the component may reset and clues to the cause of the condition will be lost.

To maintain power to the module, a small battery should be connected before it is sent to GM Engineering for analysis. Be sure to work with GM TAC, TCSC, your Field Service Engineer or other contacts to identify the best course of action with the part.

Bulletin #22-NA-205 was released recently with information about properly harvesting a module for warranty analysis. The photos in the document show an example of harvesting a Front Camera Module (FCM) from a 2022 GMC Sierra due to a parasitic drain.

Power Supply

A stable power connection to the component can be accomplished using a small 12V battery that is safe for shipping. In some cases, a larger battery may be required if a module has a high drain condition. A battery connector cable with F1 terminals also will be needed. The size of the wire and fuse will be dependent on the current draw.

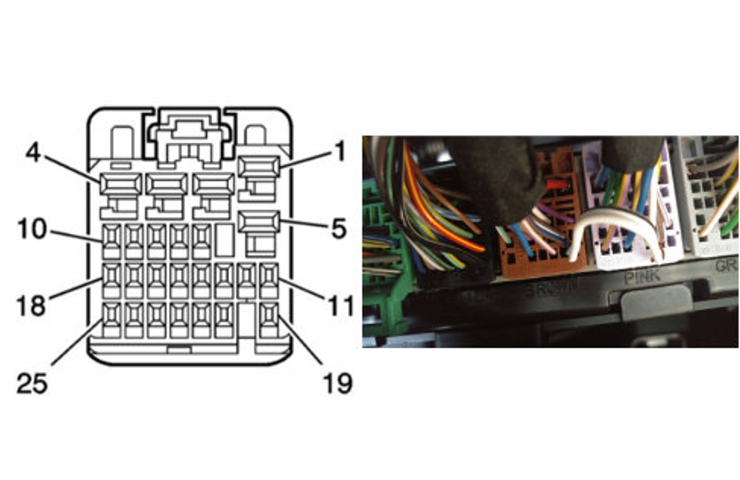

Use Service Information schematics connector end views to find the component’s pinout to identify the (-) Ground and (+) 12V power supply terminals. (Fig. 1) If there is more than one, confirm with GM Engineering if one or all pins are required to be connected.

Fig. 1

Fig. 1

Connecting Power

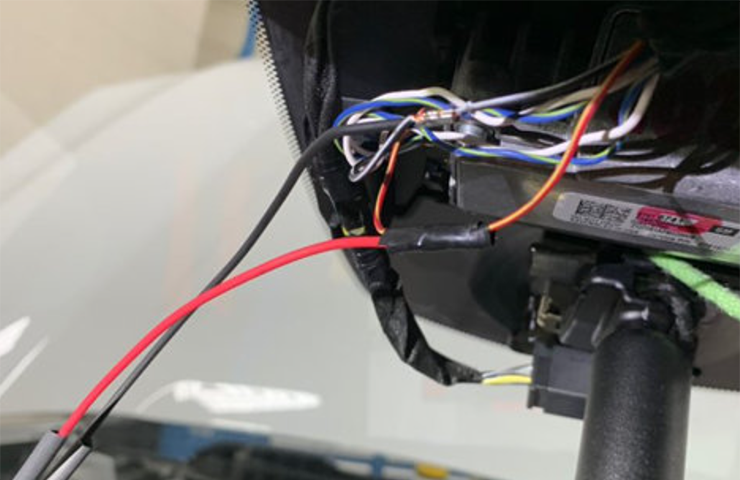

Next, after determining the best way to splice in the auxiliary power supply, expose the wiring, connect power and secure the connection. Verify the drain is still present before securing the connection. (Fig. 2)

Fig. 2

Fig. 2

Once the ground and 12V wires to the battery are connected, cut the wires on the connector one at a time to remove the battery and component out of the vehicle. (Fig. 3)

Fig. 3

Fig. 3

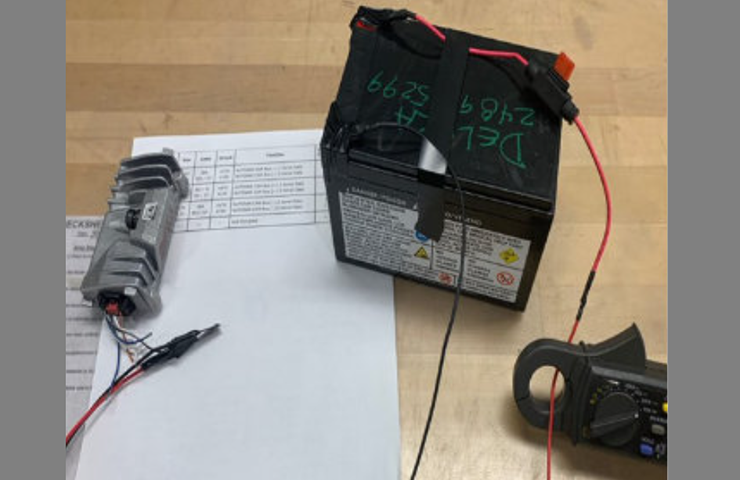

Again, if the module harvesting concerns a parasitic drain, verify that the drain is still present using a current clamp once it has been removed from the vehicle. (Fig. 4)

Fig. 4

Fig. 4

Install a new connector on the vehicle harness and verify no DTCs are set.

Packaging and Shipping

When returning the component in the failed state, firmly secure the battery and component in the shipping container to ensure the electrical connection stays secure. Also properly seal and package the component in the shipping container and label the package: UN2800 – Batteries, Wet, Non-spillable.

For complete details for powering the module and shipping all components, refer to Bulletin #22-NA-205.

– Thanks to Marco Salcedo

OLH? if not then its a no go.

I guess it needs to be done by a non flat rate employee.

The battery is a HazMat part and must be properly identified and properly shipped by someone certified in HazMat. Refer to WPC Bulletin 99-00-89-019X and DOT CFR49 regulations for more information.

question. will this method be accepted by fed ex?? or ups??

its a live circuit and would raise a red flag if x rayed by the carrier. next thing you know you have law enforcement there.

so we are mailing a box with a battery and wires connected . sound like it might raise a red flag and cause problems at the loading dock if you ask me .

you need to rethink this one

Truly understand why this is being requested, has anyone really thought about liability shipping a Component through the Mail, USPS, Fedex, UPS or whatever that is connected to a Battery, constant draw etc. Wiring connections coming loose, equals heat and smoke.

Box being scanned showing a Battery with wires attached to a component, I would elevate this for proper clearance before situations do occur. Suggest having FSE come get it.

also, how would individuals get Paid to do all of this.