Streaking is the most common warranty condition found with wiper blades on GM models. However, worn blades are not the only cause of streaking. Several other issues that can affect wiper blade performance include contamination build-up on the blade, windshield or rear glass; tears or nicks in the blade element; and non-uniform-blade element edges. Each of these potential causes should be checked when inspecting wiper blades for poor performance.

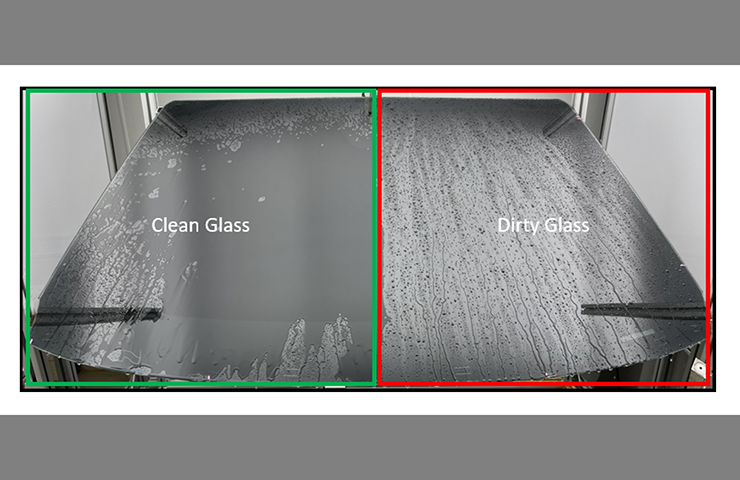

Most concerns about wiper performance are the result of dirty wiper blades, damaged wiper arms or blades, or blades that are worn beyond their useful life. Depending on environmental conditions and use, wiper blades can have dramatic differences in lifespan. (Fig. 1)

Fig. 1

Fig. 1

Let’s take a look at initial wipe quality diagnosis and evaluation, cold weather operation and a few other tips to help ensure proper wiper blade performance.

Wipe Quality Diagnosis

If the vehicle exhibits a condition where the windshield wiper blade performance is compromised, check the following items in order to properly evaluate the wipe quality:

- Determine the wiper blade warranty status. The warranty window for wiper blades is 12 months or 7,500 miles. If the vehicle exceeds either of the criteria, the wiper blade cannot be replaced under warranty.

- Clean the windshield with windshield cleaner or equivalent. The cleaner should not scratch the glass or harm the paint. (Fig. 2; Clean glass, left, and dirty glass, right)

Fig. 2

Fig. 2

- Lift each wiper blade off the windshield and clean the element with a lint-free cloth saturated with washer solvent.

- Place both wiper blades back on the glass and activate the front windshield wash system to confirm if the wipe quality concern is still present.

- If the wipe quality issue is not present, do not replace the blades. The blades should be replaced only if the wipe quality issue can be recreated after cleaning the glass and blades.

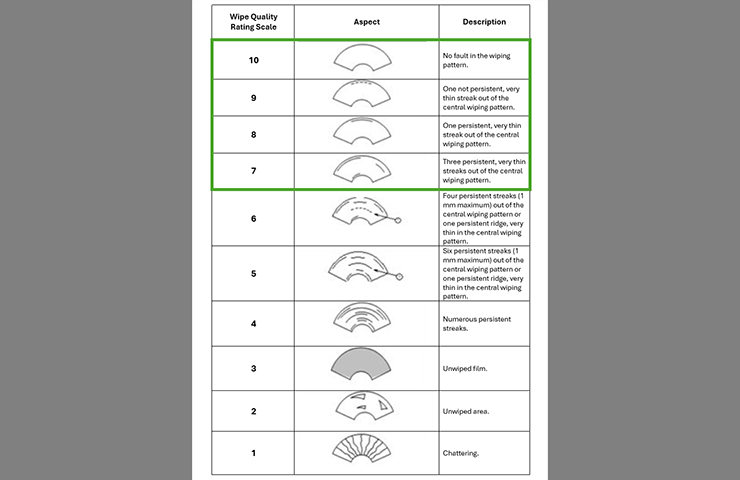

As with other criteria, wipe quality has different ratings to demonstrate ideal performance vs. degraded performance. The following chart (Fig. 3) shows the different wipe quality ratings, where GM advises any rating of 7 or higher is deemed acceptable. The wipe quality readings should be performed 3 seconds after the wipers stop.

Fig. 3

Fig. 3

Common Concerns

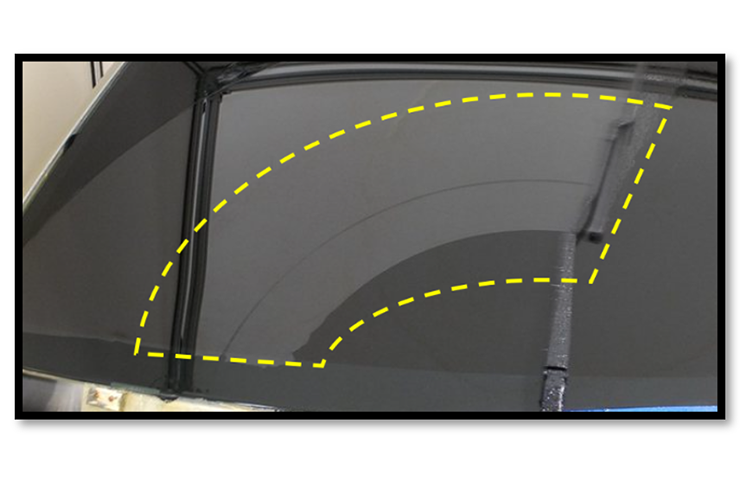

Streaking can be caused by a variety of issues (Fig. 4), including:

- Small tears in the blade element.

- Blade wear over time.

- Nicks created from attempting to clear the windshield of ice; contamination buildup on the wiper blade or windshield, such as from bugs, road grime, sap or car wash/wax treatments.

- Non-uniform blade-element edges (as manufactured).

Fig. 4

Fig. 4

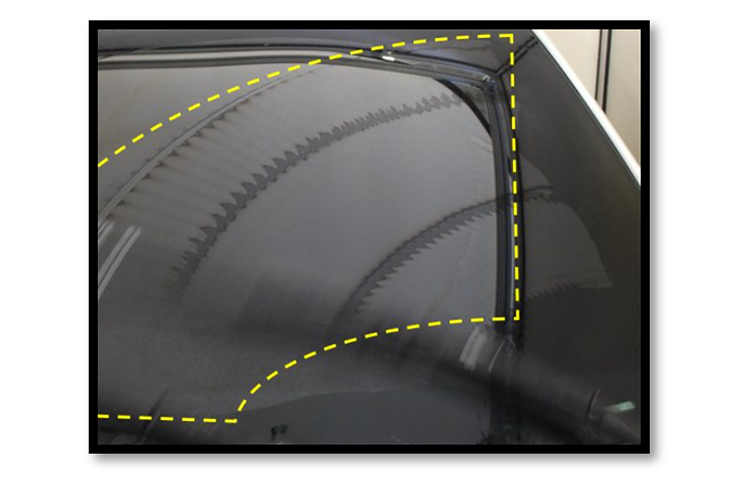

Chatter is a wiper defect where the blades move across the glass with a bouncing or uneven motion. (Fig. 5) The causes of chatter can be related to:

- The permanent set of the blade, causing resistance of the blade to flip after reversal.

- High tip force of the arm.

- Snow or ice buildup in the wiper blade hinge.

- The blade not sitting on the glass at the proper angle.

If a chatter condition still exists after a blade change, it’s possible that the tip force of the wiper arm is contributing to the chatter.

Fig. 5

Fig. 5

A number of environmental conditions can play a role in the performance and longevity of wiper blades:

- Extremely dusty areas, such as driving on dirt roads, may cause a wiper blade’s rubber edge to wear quickly and unevenly.

- Sand and salt used on roads for increasing traction and ice control during the winter may cause the wiper blades to wear more quickly.

- Areas with significant snowfall may require more frequent blade replacements.

Cold Weather Tips

Winter weather is generally a rough season for the wiper blades. The wipers should not be used to “wear through” frost or to clear snow and ice off the windshield as it can cause damage to the wiper blade’s rubber element. (Fig. 6) Instead, allow the vehicle’s defrosters to melt the frost, snow or ice, or manually clear the windshield.

Fig. 6

Fig. 6

Banging wipers on the glass to remove ice and snow also may cause the blade to bend, dislodging the rubber and causing potential scratching of the windshield.

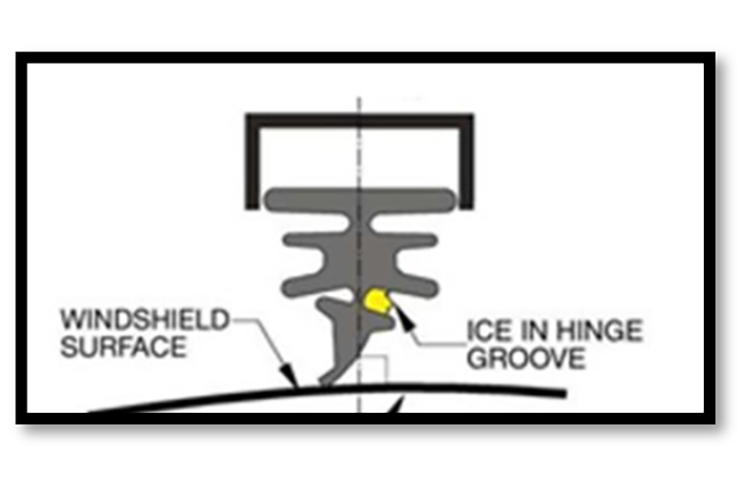

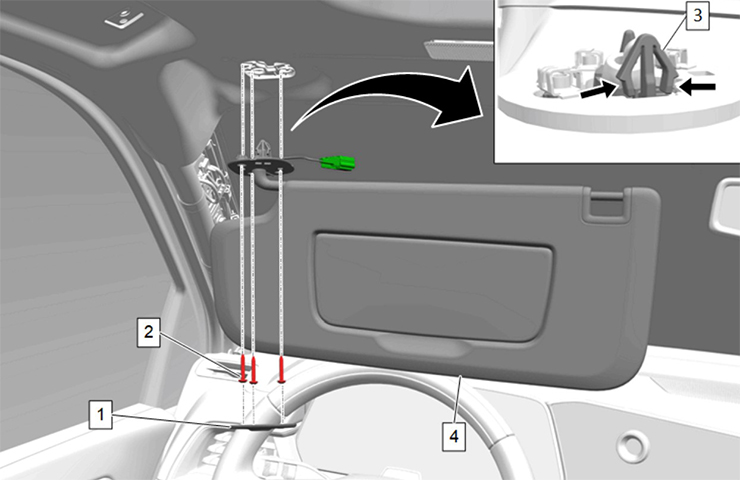

Ice in the wiper blade hinge should be cleared to allow the wiper blade to function properly. (Fig. 7)

Fig. 7

Fig. 7

Improper use of ice scrapers also can lead to wiper blade damage. (Fig. 8) Rubber blades are easily cut or torn when using ice scrapers. Avoid excessive contact with the wiper blade by moving the ice scraper parallel to the blade, which minimizes the possibility of damage. Do not pull the blades off a frozen windshield, which can tear the rubber or damage the wiper.

Fig. 8

Fig. 8

To avoid contacting the wiper blades with an ice scraper, place the wiper arms in the “service up” position, if applicable. With the wiper arms up, the wipers will not collect snow or stick to the glass, and it will prevent the ice scraper from contacting a wiper blade that is frozen to the windshield. (Fig. 9)

Fig. 9

Fig. 9

Wiper Blade Handling and Maintenance

Vehicle windshield wipers are exposed to weathering elements as soon as a vehicle is produced. Dealership policies or customer habits also can affect wiper blade performance in many ways. The following items should be considered when a vehicle is stored on the lot or a vehicle is at the dealership for service.

- During extended outdoor storage, the wiper blades may be affected by dirt and debris stuck on the blade surface. The wiper blades should be cleaned with a lint-free cloth or paper towel soaked with windshield washer fluid. Be sure to wash the windshield thoroughly when cleaning the blades.

- Tree sap and pollen should be cleared off the windshield prior to using the wipers to avoid the contamination being transferred or causing damage to the wiper blades. If possible, avoid parking under trees to prevent contamination of the wipe area. (Fig. 10)

Fig. 10

Fig. 10

- Do not operate the wipers if the vehicle is extremely dirty with gritty or sandy materials, or if there are twigs/sticks in the cowl area. If this type of debris is dragged by the force of the wipers while the windshield is dry, it may cause glass scratching.

- Drive-through car washes with wax treatment and water repellants may compromise wipe quality when the treatments cover the windshield. These treatments should be avoided to ensure proper wipe quality.

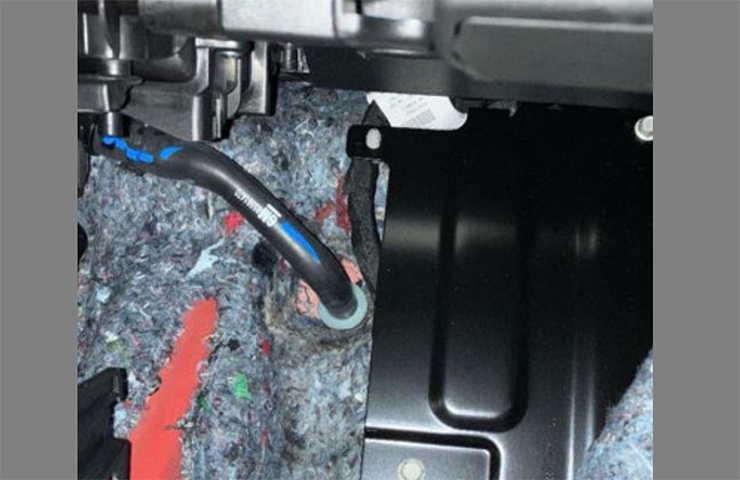

- Dealership service tickets or any paperwork should not be placed under the wiper blade. (Fig. 11) The rubber blade element should only be in contact with the glass as it can be distorted and possibly create a papercut on the blade lip.

Fig. 11

Fig. 11

- Stickers or decals should not be placed in the front or rear wipe areas as the sticker creates unnecessary wear each time it passes over the blade and compromises wipe quality. (Fig. 12)

Fig. 12

Fig. 12

- Vehicles with windshield chips or cracks in the wipe zone should be repaired to avoid tearing or creating nicks in the wiper blade element.

- Precautions should be taken when handling the wiper blade to protect the blade element and avoid distortion. For example, blades should not be stacked on one another as the blade element can be distorted and take a “set” that compromises wipe quality. Wiper blades should be kept in the protective packaging as long as possible to mitigate outside damage.

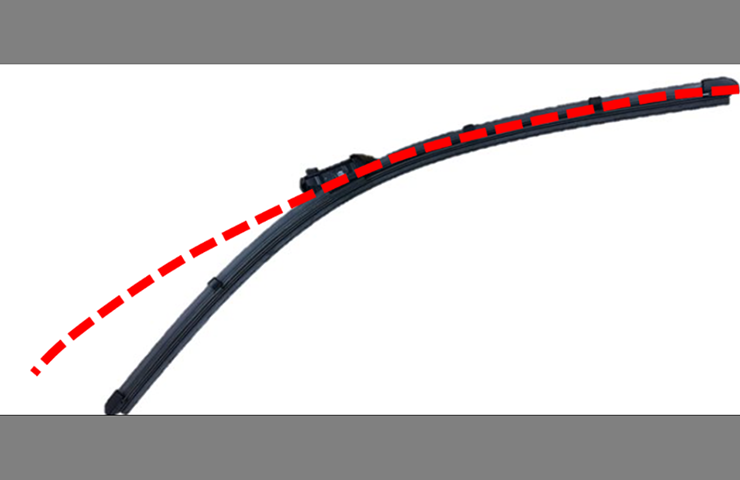

- Special care should be taken to ensure wiper blades are not straightened or bent. (Fig. 13) OEM blades are designed to fit the contour of the glass. Once wiper blades are bent, the fit to the glass is compromised and can lead to wipe quality issues.

Fig. 13

Fig. 13

Part Returns

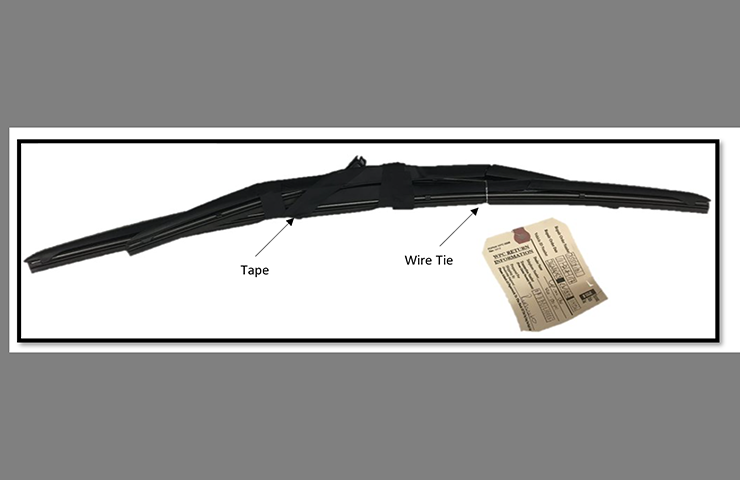

GM will occasionally open part return projects on certain vehicle programs and model years for wiper blade returns. The intention of these projects is to gain a better understanding of the issues contributing to the warranty claim by returning the wiper blade for additional analysis. If GM is requesting parts back, do not apply tape around the rubber blade element or use a twist-tie wire to secure the blades as this will distort the blade element and prevent further testing. (Fig. 14)

Fig. 14

Fig. 14

For more details about wiper blade diagnosis as well as proper handling and use, refer to the appropriate Service Information.

Thanks to Blake Whelan

Yes, well done. I started using rubbing alcohol to clean my wiper blades 10 years ago and find it does the best job in cleaning shmuck off wiper blades and have yet to find a quality wiper blade that is damaged in any way by using it.

Well Done Blake

Should think of doing this in a quick 5-10 minute video training for all too see! Also a Customer oriented video, say in the drive-thru or customer waiting area playing on one of the many tv displays!

Pretty informative!