Corroded or stripped electrical ground connections can cause a loss of module communication and other electrical system malfunctions, leading to unnecessary repairs and parts replacement. The electrical system relies on a secure, corrosion-free ground connection in order to function properly, so any damaged ground connections must be repaired to provide a good mounting point with a low resistance ground path as well as prevent future corrosion.

Ground repair connections are accomplished using one of the following replacement fasteners with a conductive finish:

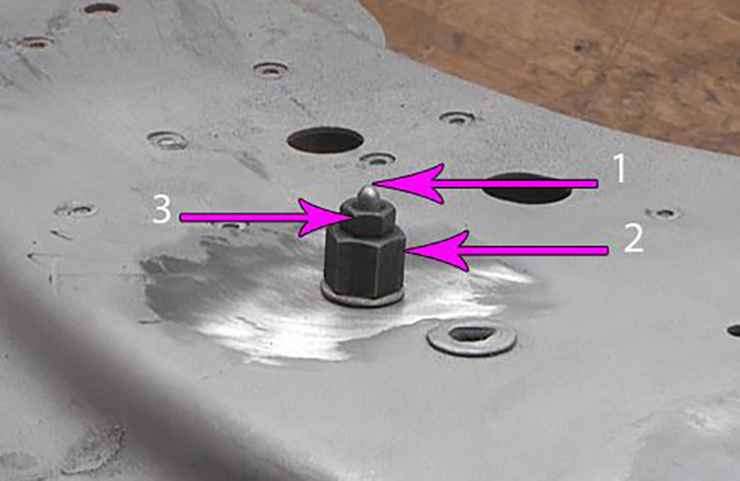

- Welded M6 stud and nut (Fig. 26)

- Welded M6 nut and bolt

- Welded M8 nut and bolt

Fig. 26

Fig. 26

Before installing a new fastener in the current ground location or at a new mounting location, remove any grease from the repair area using a residue-free solvent. Select a location that has 20 mm (0.79 in.) clearance behind the panel surface and 20 mm (0.79 in.) clearance surrounding the stud flange.

After drilling the mounting hole (for a new location), remove any paint and primer from the area until bare metal is visible. (Fig. 27)

Fig. 27

Fig. 27

Install the appropriate new fastener and check that it is securely fastened without any detectable movement.

When installing the M6 conductive rivet stud, assemble the rivet stud tool (Fig. 27, #2) with the groove and flare side facing the rivet stud (Fig. 27, #1), and then the washer and the M6 nut. (Fig. 27, #3)

Fig. 27

Fig. 27

Cover the stud threads with painter’s tape or equivalent and refinish the repair area using an anti-corrosion primer.

TIP: The surrounding area must be properly finished prior to the installation of the ground wire terminal and conductive nut to maintain a secure, stable and corrosion-free electrical ground.

Thoroughly clean the stud threads using a residue-free solvent. Once dry, apply dielectric lubricant to the threads.

TIP: Fretting corrosion is a build-up of insulating, oxidized wear debris than can form when there is a small motion between electrical contacts, causing electrical resistance across the connection.

Remove any corrosion or contamination on the electrical ground wire terminal. Install the terminal, tighten the conductive nut to the proper torque and verify system operation.

For additional details on electrical ground connection repairs, refer to the latest version of Bulletin #10-08-45-001. The bulletin includes a list of part numbers for the replacement fasteners and special tools.

– Thanks to Sherman Dixon