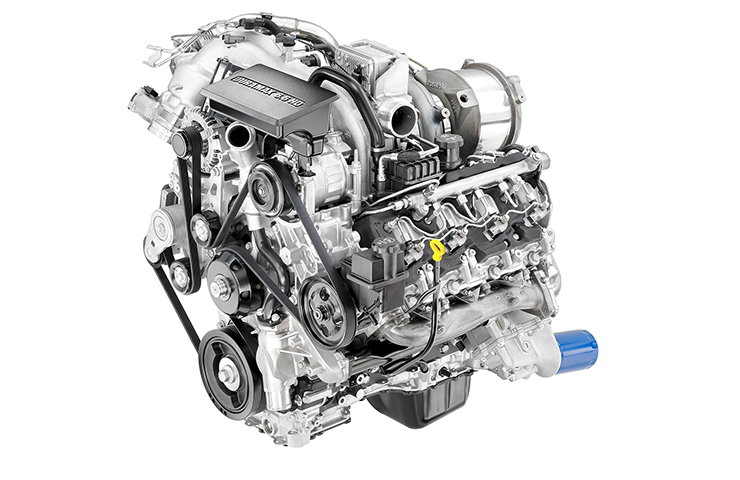

As colder winter weather rolls in, GM recommends using TOP TIER Detergent Diesel fuel in 2014-2020 GM models equipped with a diesel engine in order to maintain optimal engine performance. (Fig. 26) TOP TIER fuel can help diminish injector deposits while offering enhanced lubricity and fuel stability — key requirements for modern diesel engines.

Fig. 26

Fig. 26

If TOP TIER Detergent Diesel fuel is not available locally, GM recommends the use of ACDelco Diesel Fuel Conditioner. It is a multifunctional additive that helps clean engine deposits, improves lubricity and cold temperature fuel flow, reduces fuel filter plugging, enhances corrosion protection and fuel stability, and boosts cetane. And if low-quality fuel has already been used, GM recommends adding ACDelco Fuel System Treatment Plus – Diesel to help clean engine deposits.

TIP: Only use Ultra-Low Sulfur Diesel Fuel (ULSD) from pumps with the ULSD label. (Fig. 27)

Fig. 27

Fig. 27

If a vehicle is properly maintained but has fuel contamination issues, consider obtaining fuel from a different source. Purchasing fuel from a high volume fuel retailer increases the chance that the fuel is fresh and of good quality.

Common Diesel Fuel Concerns

Fuel Waxing/Icing – A winter fuel additive may be desired to prevent fuel waxing or icing during extreme cold snaps.

Fuel Cleanliness – Water in the vehicle’s fuel system can lead to corrosion, increased metal wear, ice during cold weather, plugged filters or screens, increased degradation of fuel, partial hydrolysis of biodiesel (FAME) in diesel/FAME blends and microbiological growth. Water is also a good solvent for inorganic salts and can contain dissolved acids or other contaminants that can harm the engine. Free water in storage or vehicle tanks can accumulate salts and polar compounds over time and severely impact fuel injection and engine operation. Elimination of water and microbial growth, along with the use of corrosion inhibitor additives, will significantly reduce the amount of corrosion and particulate generation throughout the distribution system. Diesel fuel contaminated with abrasive inorganic particles can cause abrasive wear of the fuel system and the piston rings. Fuel injectors and fuel injection pumps are particularly susceptible to wear because the high liquid pressures they generate require extremely close tolerances between parts moving relative to one another. If cleanliness concerns with diesel fuel are suspected, a sample from the fuel dispenser or fuel from the tank (1 quart or a liter) should be visually observed in a transparent container. Good fuel samples should appear to be bright and clear.

Fungi Growth – Bacteria and fungi growth can occur in diesel fuel when there is water present, especially during warmer weather. The best prevention against bacteria and fungi growth is to use clean fuel that is free of water. There are diesel fuel biocides available that are designed to kill bacterial growth in the fuel system. However, the dead bacteria can still cause blockages throughout the fuel system. If bacterial growth is found in the fuel system, the proper method of removal is to flush the fuel system using the appropriate Service Information procedures, replace the fuel filter element and refill the tank with clean diesel fuel.

Low Cetane Number – The cetane number is one indicator of a diesel fuel’s ability to ignite. There are many indicators of overall fuel quality, such as cleanliness, specific gravity, volatility, viscosity, detergency, corrosion inhibiting abilities, and lubricity. Increasing the cetane number alone is not a fix for poor quality fuel and will not increase engine performance.

Poor Lubricity – The 2.0L diesel engine and the 6.6L Duramax diesel engines are designed to operate on today’s low sulfur fuel without the use of additives. A fuel additive designed to increase lubricity is not a fix for poor quality or contaminated fuel.

Fuel Stability – Fuel Stability and degradation may be a concern for diesel fuels, especially for diesel fuel containing biodiesel. The use of aftermarket stability additives to improve the quality of a degraded fuel is not a fix and use of such aftermarket stability additives is discouraged due to concerns of proper mixing and fuel compatibility.

TIP: Any fuel additives used must not contain any metal-based additives, alcohol or other water emulsifiers that may compromise the water removal effectiveness of the fuel filtering system.

For more information about TOP TIER Detergent Diesel fuel (Fig. 28) as well as a list of TOP TIER diesel fuel retailers, visit toptiergas.com.

Fig. 28

Fig. 28

– Thanks to Larry Yaw and Shailesh Lopes

ACDelco offers two diesel fuel conditioners: 10-3011, part number 88861698, Diesel Fuel Treatment – 16 oz; and 10-3014, part number 88865597, Diesel Fuel System Treatment Plus – 11 oz.

I am having a hard time finding AcDelco diesel fuel conditioner for the new 3.0 Duramax. Is there andy other additive that you recommend?