The all-new 2020 Buick Encore GX (Fig. 10) features two new, fuel efficient, turbocharged 3-cylinder engines mated to either a continuously variable transmission (CVT) or a Hydra-Matic 9-speed automatic transmission.

Fig. 10

Fig. 10

1.2L Turbo Engine

The turbocharged 1.2L inline 3-cylinder engine (RPO LIH) is standard on front-wheel drive models. (Fig. 11) It’s paired with the VT40 continuously variable transmission (RPO MRG). The engine produces 137 horsepower and 166 lb.-ft. of torque.

Fig. 11

Fig. 11

The cylinder head is a dual overhead camshaft design made of cast aluminum alloy. Its combustion chamber contains four valves per cylinder.

The engine has two camshafts, one for the intake valves and another one for the exhaust valves. The camshafts are driven using a Belt-in-Oil system. This system reduces noise and friction compared to timing chains and dry belt systems. Both the timing belt and the oil drive belt have a change interval of 150,000 miles (240,000 km) or 15 years.

The aluminum alloy engine cylinder block is made by high pressure die casting with three cast-in-place iron cylinder liners. (Fig. 12) Of the four crankshaft bearings, the thrust bearing is located on the third bearing from the front of the engine. A lower structural extension forms the lower portion of the crankcase to promote cylinder block rigidity and reduce engine noise and vibration.

Fig. 12

Fig. 12

The cast aluminum pistons are a lightweight and low-friction design with a recessed top and a barrel-shaped, graphite-coated skirt. The pistons use two compression rings and one oil control ring assembly. The chromium steel pins are designed to be full-floating and must be serviced with the pistons as an assembly.

The oil cooler heat exchanger is mounted to the lower left side of the engine, on the coolant pump housing, and is used to cool the engine oil.

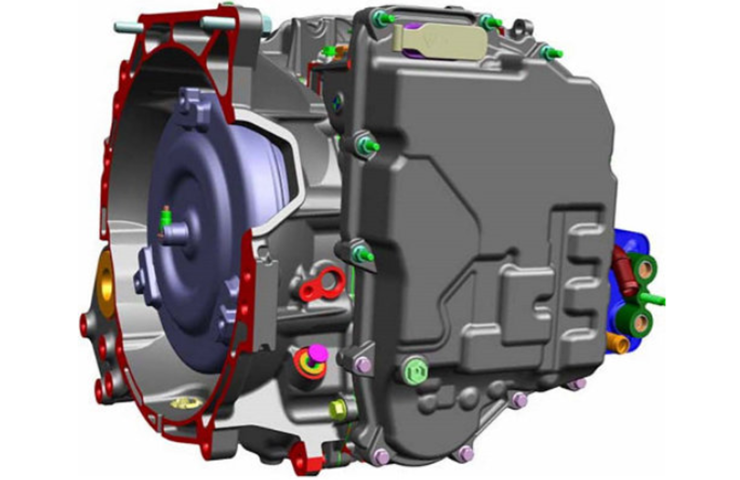

CVT Transmission

The VT40 is a fully automatic single mode continuously variable, front-wheel drive transmission. (Fig. 13) The transmission features:

- a four-element torque converter

- one planetary gear set

- an electronic hydraulic pressurization and control system

- a variable drive and driven pulley assembly

- variable drive chain

- two friction clutches

- a differential assembly

Fig. 13

Fig. 13

The four-element torque converter contains a pump, a turbine, a pressure plate splined to the turbine, and a stator assembly.

The transmission fluid pump is a binary vane type, which effectively allows for two pumps in the packaging size of one. The design of the pump provides for ideal oil routing to the controls system, with the pump located in the valve body itself.

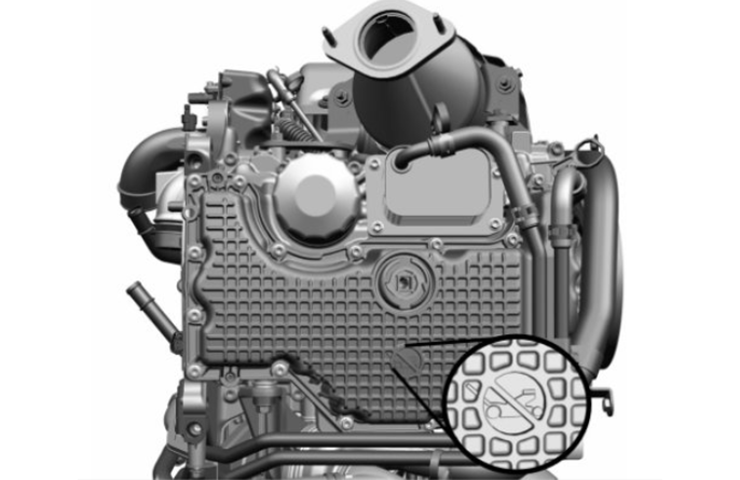

1.3L Turbo Engine

All-wheel drive models of the Encore GX feature the turbocharged 1.3L inline 3-cylinder engine (RPO L3T). (Fig. 14) The engine also is optional on some front-wheel drive models. Built using the new cylinder set strategy (CSS) engine architecture, it delivers 155 horsepower and 174 lb.-ft. of torque.

Fig. 14

Fig. 14

It features many of the same structural elements of the new 1.2L engine, including an aluminum alloy engine block and cylinder head as well as cast aluminum pistons.

The lubrication system includes a continuously variable oil pump, an oil filter bypass valve, and an oil heat exchanger, which is mounted to the lower right side of the engine. The lower oil pan is made of plastic and is attached at the engine block lower structural extension. The oil pan must not be used for lifting the engine, as noted by the icon on the pan. (Fig. 15) These oil pans are equipped with M5 jackscrews for easy removal. Once properly cleaned, the oil pan is reusable.

Fig. 15

Fig. 15

The camshaft actuator system on the cylinder set strategy engine is much like the camshaft actuator systems found on other GM engines. The system enables the Engine Control Module (ECM) to change camshaft timing while the engine is running. The intake and exhaust camshaft position actuator assemblies vary the camshaft position in response to directional changes in oil pressure, providing enhanced power and efficiency. There are two camshaft position sensors, integrated into the camshaft cover, that send feedback to the ECM.

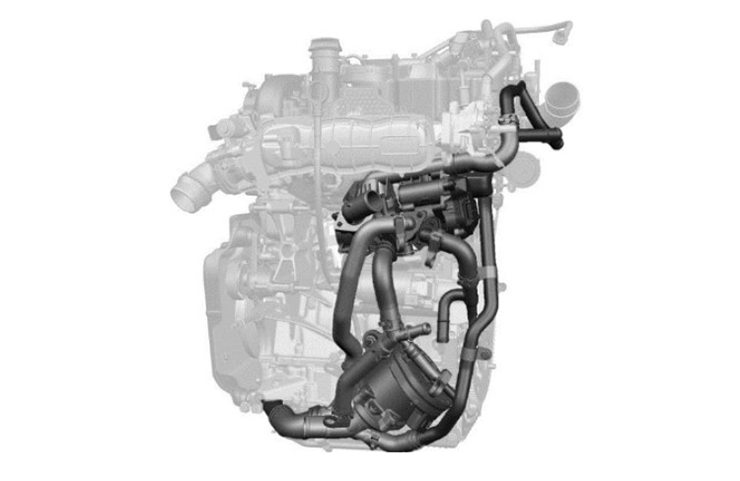

The cooling system on the cylinder set strategy engine is called active thermal management and is used to control the coolant temperature. (Fig. 16) The system helps the engine and transmission warm up in order to reach its optimal temperature more quickly. Likewise, this system cools the engine and transmission when necessary for high power operation.

Fig. 16

Fig. 16

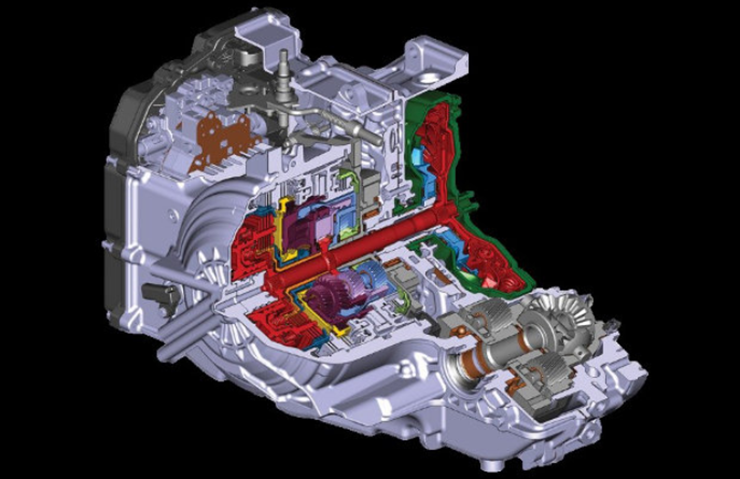

9-Speed Automatic Transmission

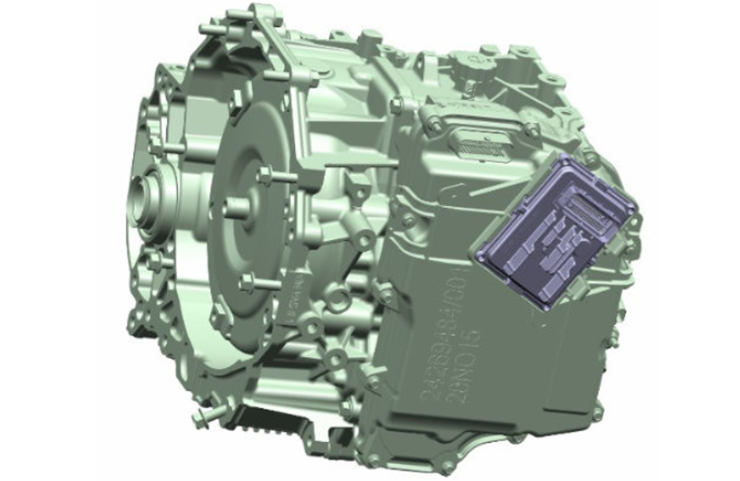

The Hydra-Matic 9T45 transmission is a fully automatic, 9-speed, transverse-mounted, electronically-controlled transmission. (Fig. 17) It consists primarily of a 4-element torque converter, a compound planetary gear set, friction and mechanical clutch assemblies, and a hydraulic pressurization and control system. The multiple disc clutches combine with the selectable one-way clutch to deliver ten different gear ratios — nine forward and one reverse.

Fig. 17

Fig. 17

The selectable one-way clutch has two modes of operation. In the released mode, it will hold in one direction and free wheel in the other direction. In the applied mode, it holds in both directions.

The Transmission Control Module (TCM) is a standalone unit mounted to the front of the transmission. (Fig. 18) The 9T45 9-speed transmission uses a line pressure control system during upshifts to compensate for new transmission build variation and the normal wear of transmission components. The TCM adjusts the pressure commands to the various control solenoids to maintain the originally calibrated shift timing.

Fig. 18

Fig. 18

For additional information on the all-new 2020 Encore GX, refer to Bulletin #20-NA-032.

– Thanks to Frank Jakubiec and Matt Bunting