Using the correct fastener in a given location can’t be stressed enough when performing repairs on today’s modern vehicle designs. Here’s an example why.

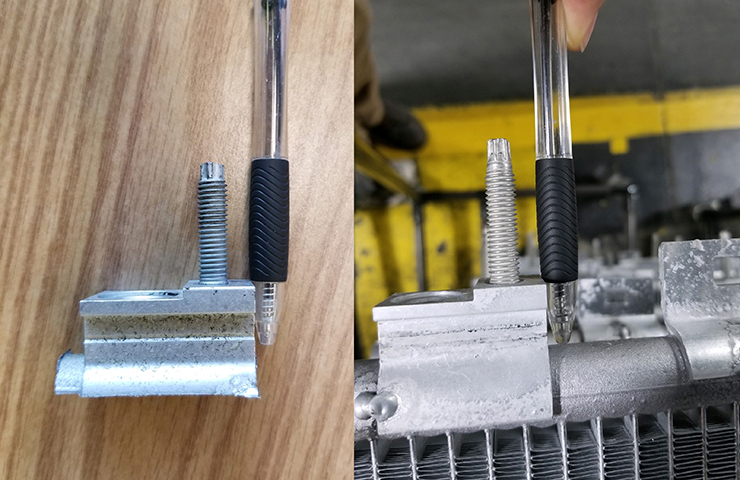

A recent analysis of an air conditioning warranty claim on a 2020 Silverado 1500 with a refrigerant leak led to an unlikely cause. An inspection of the A/C condenser that was replaced showed a stud (Fig. 14, right stud) at the A/C condenser manifold block had been replaced with a different stud (Fig. 14, left stud) that was longer.

Fig. 14

Fig. 14

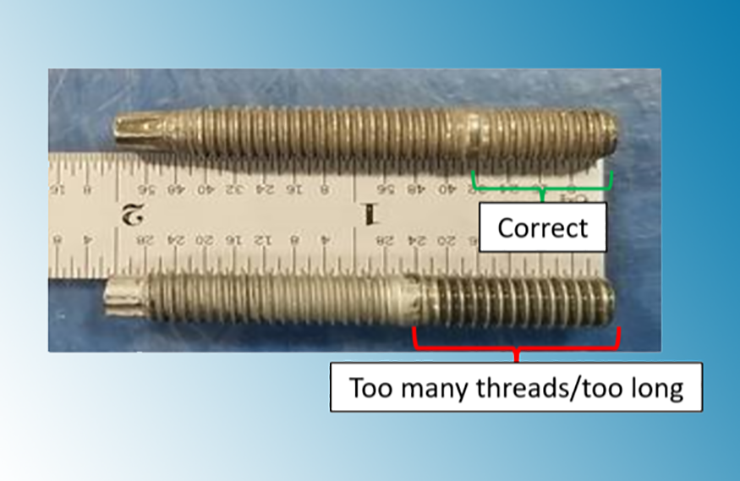

The original, correct stud and the new, incorrect stud appeared to be the same length, but the incorrect stud could be driven deeper into the manifold. (Fig. 15)

Fig. 15

Fig. 15

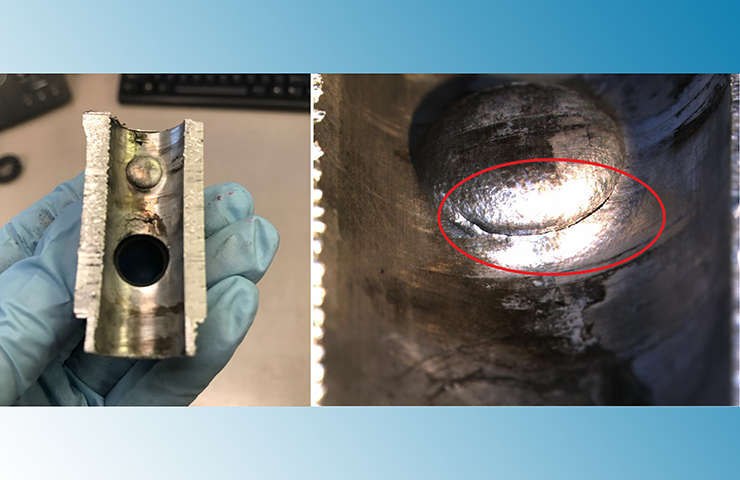

When the incorrect stud was driven into the manifold (Fig. 16, left), it bottomed out in the hole and punched through the condenser manifold, causing a slight crack (Fig. 16, right) and, eventually, a refrigerant leak.

Fig. 16

Fig. 16

Replacement Fasteners

Any time a fastener is threaded into a component, it’s imperative that the fastener used be the correct one for that application. In the past, when components had extra mass and were made of materials such as steel or iron, a fastener that would bottom out in a hole would most like not result in any damage. Modern vehicle designs today are highly mass-optimized, meaning parts are made of materials that are thinner and lighter and are made for a specific operation. Any unnecessary material has been removed as part of the design process.

It may not be apparent when a stud or bolt runs out of thread and breaks through into a cavity underneath and creates a leak. The leak may not be apparent for hundreds of miles, which leads to a more difficult diagnosis down the road.

The Service Information calls out the importance of using the correct fasteners, tightening sequence, and torque specifications in every threaded joint repair procedure.

Caution: Use the correct fastener in the correct location. Replacement fasteners must be the correct part number for that application. Do not use paints, lubricants, or corrosion inhibitors on fasteners, or fastener joint surfaces, unless specified. These coatings affect fastener torque and joint clamping force and may damage the fastener. Use the correct tightening sequence and specifications when installing fasteners in order to avoid damage to parts and systems. When using fasteners that are threaded directly into plastic, use extreme care not to strip the mating plastic part(s). Use hand tools only, and do not use any kind of impact or power tools. Fastener should be hand tightened, fully seated, and not stripped.

GM Engineering Standards and North American Industries have adopted a portion of the ISO-defined standard metric fastener sizes in order to reduce the number of fastener sizes used while retaining the best thread qualities in each thread size.

Check for the correct fasteners for an application during repairs. Simply choosing fasteners that look similar in size is not a reliable method for identifying the proper fasteners. Always identify the fastener by the part number identified in the repair procedure. Also, always be sure to torque all fasteners to the provided torque specifications.

– Thanks to David MacGillis, Scott Chalmers and Frank Robinson