Some 2021 Tahoe, Suburban, Yukon and Escalade models equipped with the available Air Ride Adaptive Suspension (RPO F47) may have a suspension trim height that is too high or too low at one or more corners along with a Driver Information Center message (Leveling Unavailable, Service Air Suspension, and/or Speed Limited). The following DTCs also may be set: C1190, C1191, C1192, C1193, C1187, C1188, C1189, C118A, C118B, C118C, C118E, and C118F.

The Air Ride Adaptive Suspension offers a variable spring rate, automatic load leveling and up to 4 inches of ride-height adjustment. The four air springs raise or lower vehicle height based on the automatic level control module inputs. (Fig. 1) Airflow to the four air springs is determined by the pneumatic control unit, which contains the pressure sensor and control solenoid valves for each spring.

Fig. 1

Fig. 1

The air springs may become over- or under-inflated if one or more of the air lines is not fully seated into an air spring or air manifold block assembly, causing the suspension trim height conditions to occur.

Check the Fittings

An air line that is not fully seated can cause an air spring to be under inflated, due to the air leaking out, as well as lead to over-inflated air springs due to the one-way check valve in the air line fitting.

The one-way check valve in the air line fitting is used during manufacturing to keep a small amount of air inside the air spring before it is installed on the vehicle. Once the air spring is installed and the air line is fully seated into the air spring fitting, the check valve is no longer needed and the air line holds the check valve open. However, if the air line is not fully seated into the fitting, it will not fully open the one-way check valve. When this occurs, air can be pushed past the check valve into the air spring, but air cannot be released. As a result, the air spring will inflate but will not deflate since it cannot release the air from inside the air spring.

Since the seating of the air fittings is critical for proper operation, there are white marks on each air line to indicate when the air line is fully seated. The air line has to be inserted into the air fitting until it bottoms out and the white marks on the air line are going into the fitting. (Fig. 2) At least part of the white marking must be in the top of the fitting.

Fig. 2

Fig. 2

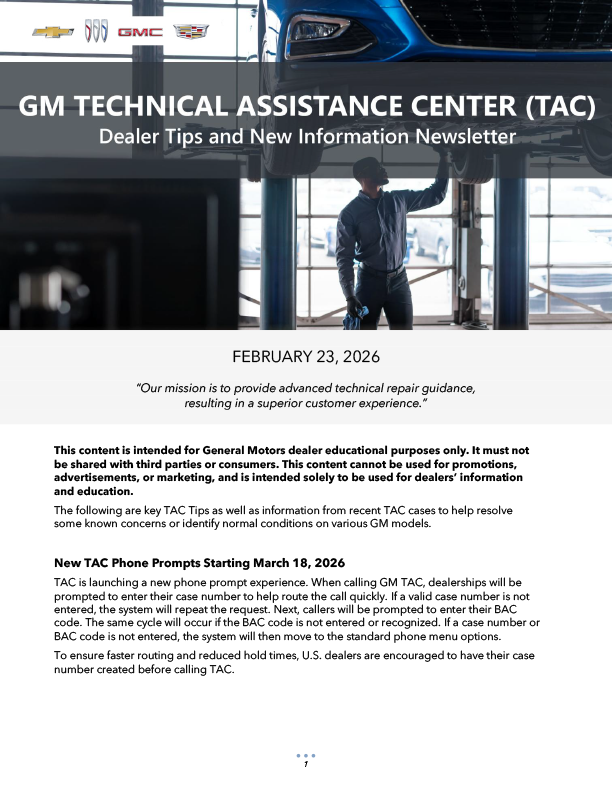

If the air line at the air spring is not fully seated, the white marking will not be going into the fitting and there will be space between the marking and the fitting. (Fig. 3)

Fig. 3

Fig. 3

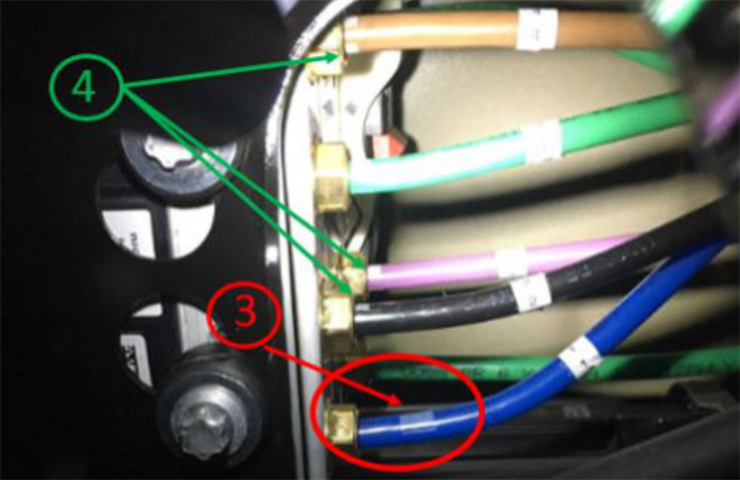

At the air manifold block, the air lines must be fully seated in the same manner, indicated by the white markings going in the top of each air line fitting. The blue air line shows an example of a line that is not fully seated with the white marking not going into the air line fitting. (Fig. 4)

Fig. 4

Fig. 4

Testing the Air Springs

Inspecting each air line to ensure that the white marking goes into each fitting at the four air springs and manifold valve block will help in determining the cause of a low, high or uneven suspension condition. If an air line is not fully seated, push the air line into the fitting until it bottoms out and the white marking is going into the top of the fitting. In most cases, there is no need to loosen the air line fitting to fully seat the air line.

GDS2 can be used to test for an air spring that will not deflate due to the air line not being fully seated into the air spring. If this condition exists, suspect the side or corner that is sitting higher than the others. For example, if the vehicle sits high on the left side, then suspect the left side air springs are not able to deflate. Any air lines that are kinked, pinched or damaged should be replaced.

GDS2 also can be used to test for an under inflation condition where the air line is not fully seated and leaking air. In this case, suspect the side or corner that is low. For example, if the vehicle sits very low on the left side, then suspect that the left side air spring lines may be leaking.

Refer to #PIT5801 for complete testing information using GDS2.

TIP: In addition to the air line connections, there may be other issues that can cause over- or under-inflated air springs. Follow all procedures in the appropriate Service Information when working on the air suspension system.

If the vehicle was driven for a period of time with no air pressure in an air spring, it may have damaged the air spring. Inspect the inflated air spring and if damage is found, the air spring should be replaced.

Service Mode

When the air suspension system is in service mode, all air suspension operations, including raising and lowering the vehicle and air compressor operation, are disabled. Service mode is useful when a vehicle is placed on a hoist during service or being towed on a flat bed.

Service mode is automatically enabled when the vehicle is raised on a hoist or a floor jack. Service mode automatically disables when vehicle speed exceeds 10 mph (16 km/h). Service mode also can be manually enabled and disabled in the Settings menu by selecting the Suspension option.

For additional information, refer to #PIT5801.

– Thanks to Jim Will