Some 2016-2020 Express and Savana models equipped with the 6.0L V8 engine (RPO L96, LC8) may have a lack of power or poor performance when driving up grades or after the vehicle has been idling for long periods of time in high ambient temperatures (90°F, 32°C, or above). At lower temperatures, these conditions may be less noticeable or eliminated. The poor performance may be more noticeable when the vehicle is outfitted with heavy work equipment, such as work boxes or ambulance bodies, and is driven in stop-and-go traffic.

At high ambient temperatures of 90°F (32°C) or above, the intake airflow to the engine may be reduced. The GDS2 scan tool data may show an increase in total knock retard and the ignition timing may be backed out, which may occur while the vehicle is under a load or driving in a situation where more throttle input is required, including going up a grade. The Engine Control Module (ECM) is adjusting to protect the engine from damaging spark knock, which is normal under these conditions.

If these conditions are found, the grille and radiator air upper baffle should be modified and a new engine air inlet duct extension installed to increase airflow. The new duct will pull air from outside the hood seals.

Refer to Bulletin #21-NA-260 for a number of components to inspect before modifying the air inlet duct as well as the complete duct extension installation procedure.

Installing the Air Inlet Duct

Installing the new engine air inlet duct requires removal of part of the grille material on the right side of the grille. (Fig. 10)

Fig. 10

Fig. 10

When cutting the grille, do not cut through either standing rib. The ribs must be kept intact. (Fig. 11)

Fig. 11

Fig. 11

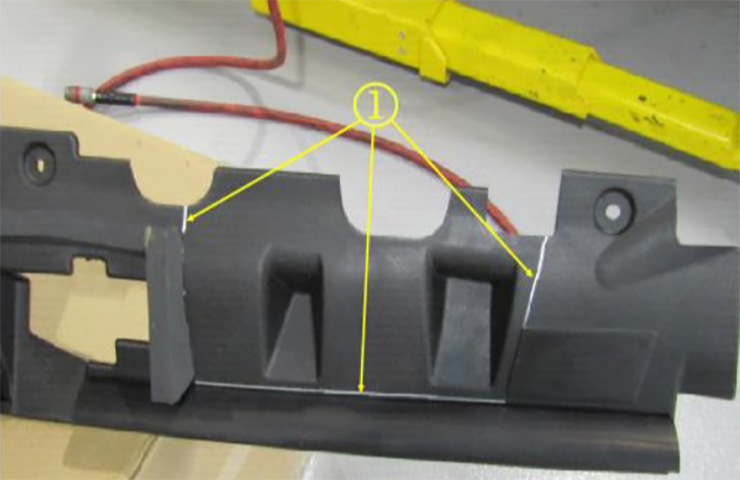

The radiator air upper baffle part also must be modified to allow for clearance of the engine air inlet duct. (Fig. 12)

Fig. 12

Fig. 12

The new engine air inlet duct should be sealed with RTV engine sealant around the complete perimeter of the upper opening at the interface to the intake duct. Three push retainers are used to secure the duct to the vehicle. (Fig. 13)

Fig. 13

Fig. 13

For additional information and part numbers, refer to Bulletin #21-NA-260.

– Thanks to Matt Singer