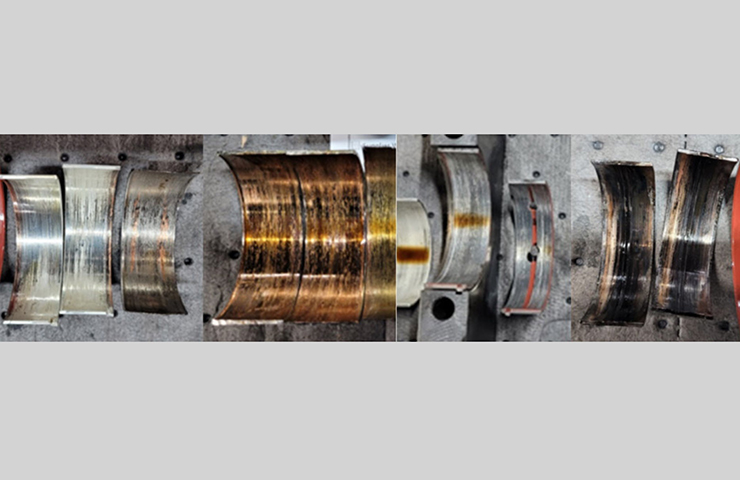

If a gasoline engine is being replaced on a 2000-2022 GM passenger car or truck due to a connecting rod or crankshaft main bearing failure (Fig. 27), there are several guidelines to follow to ensure proper operation of the new service engine.

Fig. 27

Fig. 27

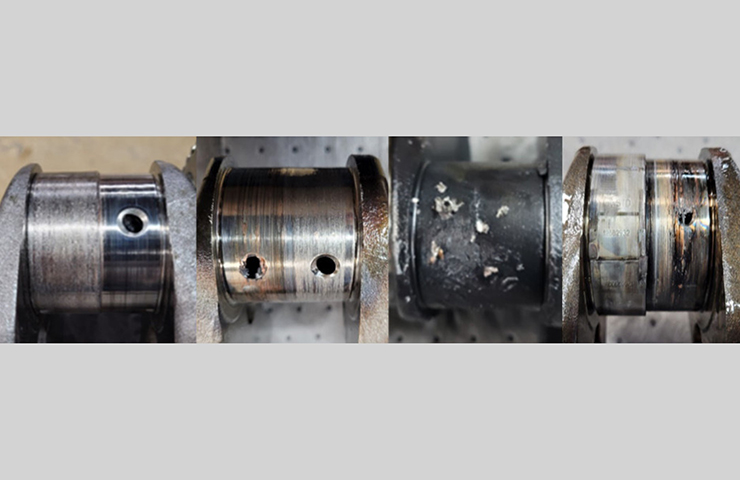

If an engine experiences failure due to a damage from a connecting rod (Fig. 28) or crankshaft main bearing, it is necessary to replace the oil cooler, oil cooler lines and oil tank, if equipped. Debris from a damaged rod or main bearing will be sent directly through the oil galleries and components that are in the lubrication circuit.

Fig. 28

Fig. 28

Since the complex oil gallery passages make thorough and complete component cleaning difficult, oil cooler, oil cooler line and oil tank replacement is required. Reinstallation of an oil cooler and/or cooler line that were removed from an engine with rod and/or bearing failure debris may result in the transfer of any remaining debris into the new service engine, which may then lead to possible damage or failure of the new service engine long block.

TIP: Some service engines come with the oil cooler and/or oil cooler lines already attached to the new service engine. In this case, replacement of these components is not necessary.

For more information, refer to Bulletin #22-NA-074.

– Thanks to Bryan Salisbury