When addressing an engine misfire condition on some 2014 Silverado 1500, Sierra 1500; 2014-2019 Corvette; 2015-2018 Silverado, Sierra; 2015-2020 Tahoe, Suburban, Yukon, Escalade; 2016-2019 CTS-V; 2016-2023 Camaro; and 2019 Silverado LD and Sierra Limited models equipped with the 5.3L V8 engine (RPO L83, L8B) or 6.2L V8 engine (RPO L86, LT1, LT4)., the valve lifter oil manifold assembly (LOMA) should be replaced only if the diagnostics in the appropriate Service Information lead to a fault within the manifold assembly.

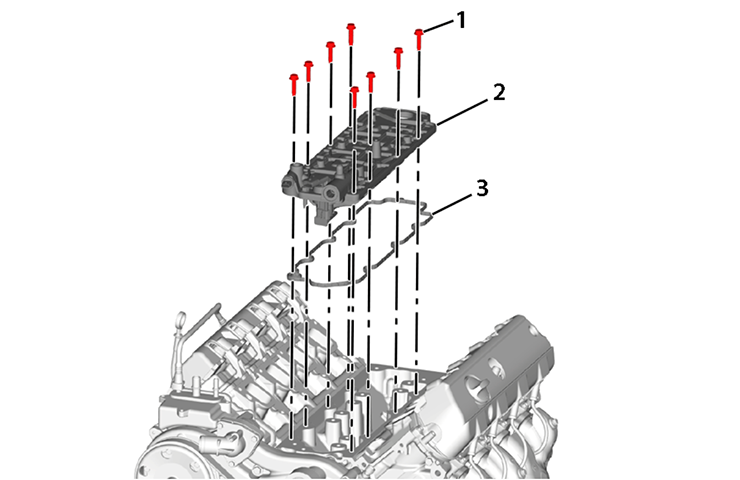

The part numbers have been updated for the individual components that were previously included in the valve lifter oil manifold (VLOM) kit. With the updated part numbers, select only the parts that coincide with the repair being performed. The VLOM should be replaced only if it tests faulty. (Fig. 6)

Fig. 6

Fig. 6

Bulletin #15-06-01-002O includes an updated parts list. Replace the part with the P/N outlined in the Electronic Parts Catalog (EPC) in accordance with the vehicle VIN.

Check Valve Lifter Operation

Possible causes of the misfire condition include an Active Fuel Management (AFM) lifter that is mechanically collapsed and/or stuck all of the time, internal locking pin damage in the lifter due to oil aeration, a collapsed lifter that is stuck in the lifter bore, or a bent pushrod.

During diagnosis, inspect the valve operation. If the valves are not moving, it may be necessary to replace the valve lifter oil manifold and the affected bank of AFM lifters. If the lifter has spun the bore, the guides also should be replaced.

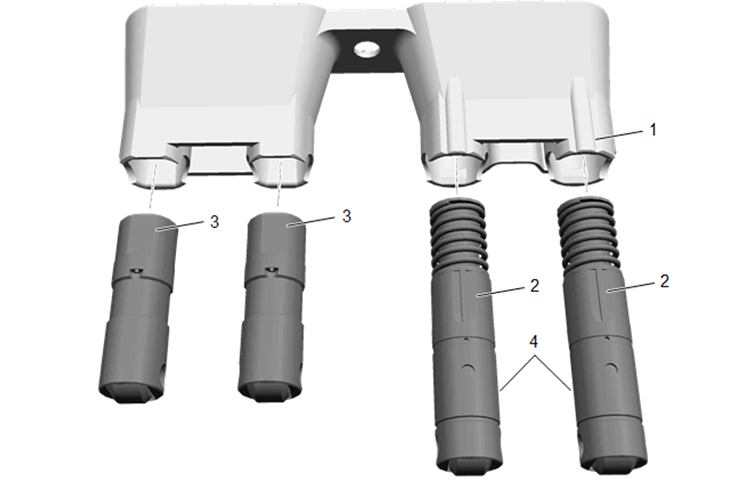

TIP: Any time a lifter is replaced, the lifter guide also must be replaced. (Fig. 7)

Fig. 7

Fig. 7

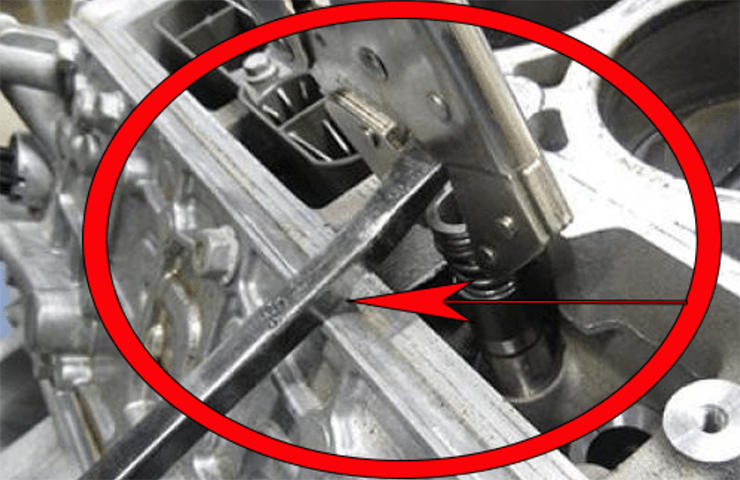

If a lifter is stuck in the bore, use vice grips with a slide hammer or a small pry bar to remove the lifter. Do not pry on the sealing surface of the block when removing a lifter. (Fig. 8)

Fig. 8

Fig. 8

For more information and part numbers, refer to Bulletin #15-06-01-002O.

– Thanks to Bryan Salisbury

Cylinder deactivation system testing information can be found in Service Information document ID #3258532. Manifold testing requires use of several special tools and a minimum shop air source of 30 psi.

We”ve had few of the vloms pass the test when they are cold but after replacing the lifters, they came back a week or so later with lifter issues again, our policy has always been to replace the vlom, does the vlom need to be warmed up to properly test it?