If the engine for a GM model needs to be replaced with a new engine or has to be overhauled, be sure to perform the Engine Prelubing procedure as part of the installation process. Failure to complete the engine prelubing may result in premature crankshaft bearing and engine wear.

TIP: Prelube is necessary if the engine is replaced or overhauled. If not completed, a debit to the dealership can be assessed for engine failures.

Engine Prelubing before Accessory Drive Belt Installation

The Engine Removal and Installation service procedure was recently reviewed for the 5.3L engine (RPO L84), 6.2L engine (RPO L87) and 6.6L engine (RPO L8T). To help prevent bearing damage, the Engine Prelubing step has been moved before the installation of the accessory drive belts.

The reason this change was made is to ensure the lower crankshaft bearings and journals have an adequate amount of oil before rotating the engine dry during drive belt installation.

The revised step sequence can be found in the Engine Removal and Installation procedure, Document ID 6720543. (Fig. 1)

Fig. 1

Fig. 1

Engine Prelubing

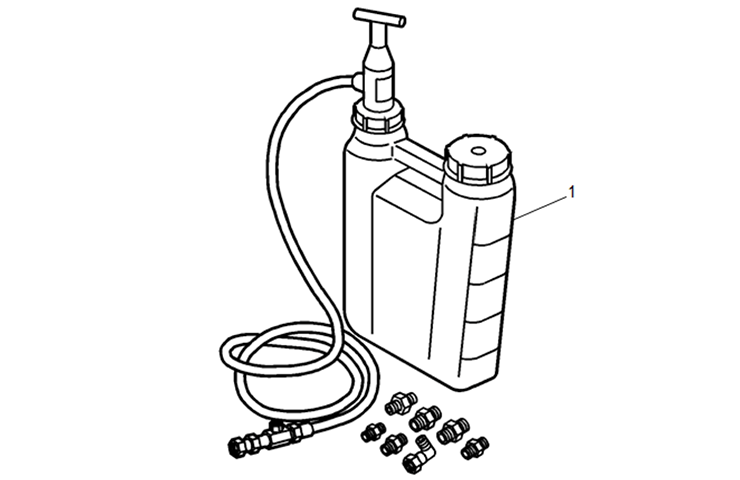

The engine prelubing procedure requires using the EN-45299 Engine Preluber (Fig. 2) and EN-47971 Oil Pressure Gauge Adapter to help provide a constant and continuous flow of clean oil to properly prime the engine.

Fig. 2

Fig. 2

After attaching the Engine Preluber to the Oil Pressure Gauge Adapter, use the Engine Preluber to pump a minimum of 1-2 quarts (1-1.9 liters) of new engine oil into the engine assembly.

Refer to the appropriate Service Information for complete details of the Engine Prelubing procedure.

– Thanks to Bryan Salisbury

justin, N252494000-07 Document ID: 6995271, step 31…If the engine FAILS the test, refer to Engine Replacement in SI. Transfer the engine oil cap from the original engine to the replacement engine and fill the engine with the oil grade that is indicated on the cap.

why isn’t this done at the factory when you can access every single port / passage you want !

They do have some assembly lube on them, but some engines can sit for periods of time before being used, which means the oil galleries and other lube circuits are still dry at this point.

When replacing an engine use the oil that is designated on the oil fil cap.

Prelube is not only important for the bearings, but it also ensures the oil galleries and other lube circuits are primed with oil before the first start.

That’s wonderful. But, if we are so concerned about bearing damage from rotating the engine, shouldn’t the prelubing be done BEFORE we install the torque converter bolts in step 28 VS at step 231??

Haven’t read this entire “new” procedure, as need to read over 221 steps to find this one, but the engine does have to be turned to install torque converter bolts, which I’m assuming is a prior step to installing the belts. Yup, step 29. “The reason this change was made is to ensure the lower crankshaft bearings and journals have an adequate amount of oil before rotating the engine dry during drive belt installation.”

After replacing the engine. Should I update the engine oil to 0w40 or use same as 0w20?

So aren’t these bearings suppose to been lubed during assembly?