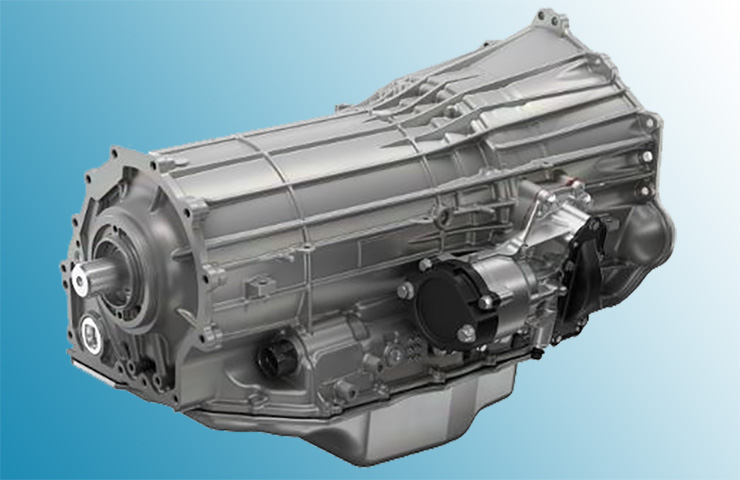

The all-new Allison 10-speed 10L1000 automatic transmission (RPO MGM, MGU) available on 2020 Silverado HD and Sierra HD models equipped with the 6.6L Duramax diesel engine combines enhanced performance, fuel economy, and operational flexibility with an industry-leading reputation for reliability. Designed for high-performance and low-maintenance, the new 10-speed transmission (Fig. 14) — the first-ever offered in the heavy-duty pickup segment — has been tested and validated in partnership with Allison Transmission and, combined with the proven Duramax 6.6L diesel engine, offers a powertrain combination that provides superior power delivery and productivity.

The Duramax/Allison powertrain standard axle ratio has been reduced to 3.42:1, which lowers engine speed, enhances refinement and increases efficiency. The powertrain combination is available on 2WD or 4WD models.

Fig. 14

Fig. 14

Transmission Architecture

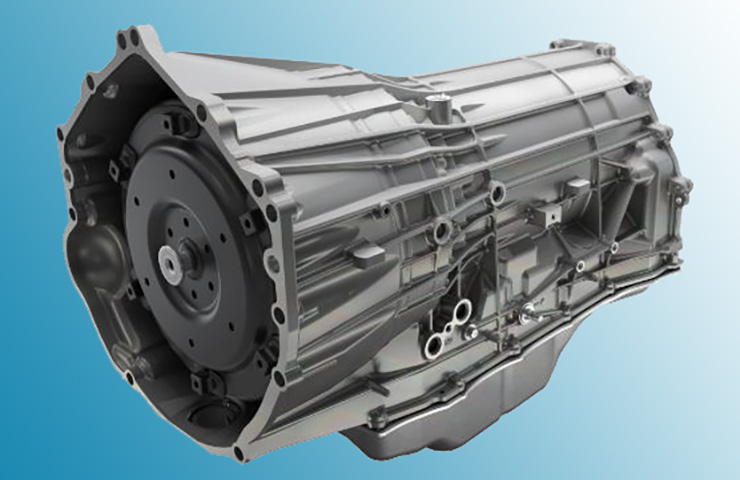

The transmission has 10 speed ratios that are generated using four simple planetary gear sets, two brake clutches, and four rotating clutches. The on-axis transmission architecture uses a squashed torque converter, an off-axis pump and four close-coupled gear sets. The four rotating clutches are located forward of the gear sets to minimize the length of oil feeds that provide for enhanced shift response. There are different variants of the transmission, all based on torque capacity. Architecture is common between the variants, and component differences are primarily related to size.

The transmission architecture features a case with an integral bell housing for enhanced powertrain stiffness. (Fig. 15) A unique pump drive design allows for off-axis packaging very low in the transmission. The pump is a variable vane type, which effectively allows for two pumps in the packaging size of one. This design and packaging strategy provides for ideal oil routing to the controls system with the pump located in the valve body itself.

Fig. 15

Fig. 15

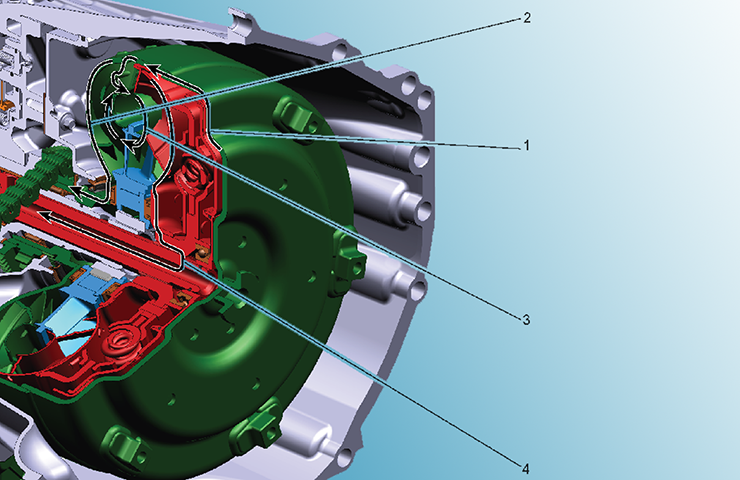

The 4-element torque converter contains a pump, a turbine, a pressure plate splined to the turbine, and a stator assembly. (Fig. 16) The torque converter acts as a fluid coupling to smoothly transmit power from the engine to the transmission. It also hydraulically provides additional torque multiplication when required. The pressure plate, when applied, provides a mechanical direct drive coupling of the engine to the transmission.

Fig. 16

Fig. 16

The hydraulic system primarily consists of an off-axis gear-driven variable vane-type pump next to the valve body, and two control valve body assemblies. The pump maintains the working pressures needed to stroke the clutch pistons that apply or release the friction components, which consist of six multiple disc clutches. The multiple disc clutches deliver 11 different gear ratios, 10 forward and one reverse, through the gear sets.

Transmission Control Solenoid Valves

The Transmission Control Module (TCM), which is externally mounted, uses three speed sensor signals for enhanced shift response and accuracy .The TCM receives and monitors various electronic sensor inputs and uses this information to shift the transmission at the optimum time.

The 10-speed transmission could contain a maximum of nine individual solenoids — RPO dependent — installed in various bore locations on the lower control valve body assembly and internal transmission case. Eight of the nine solenoid valves are used to control pressure regulation and direction of transmission fluid. The one on/off solenoid valve is only used to direct transmission fluid. The normal operating current range for these solenoid valves is between 0–1.2 amps. If the TCM detects an electrical circuit malfunction or excessive current flow, the TCM will turn off the high-side driver to that solenoid and set a DTC.

Transmission control solenoid valves 1–8 are pressure regulating valves. Each solenoid valve is tested after assembly to determine the output fluid pressure at certain electrical values, applied to the coil winding, and is referred to as solenoid current/pressure data points. The current versus pressure data points are saved and assigned a file number, which is marked on the solenoid valve housing end or on the valve body itself. The solenoid performance data file is programmed and stored in the vehicle’s TCM as well as stored on the Techline Information System (TIS) website. Replacing any of the following components require the TCM to be programmed with either the new or existing solenoid valve performance data, depending on what component is replaced.

- Transmission assembly – program the TCM with the new data file stored on the TIS web site for all pressure regulating solenoid valves.

- Lower control valve body assembly with solenoid valves – program the TCM with the new data file stored on the TIS web site for all pressure regulating solenoid valves.

- Transmission Control Module – program the TCM with the existing data file stored on the TIS web site for all pressure regulating solenoid valves.

- One or more solenoids – program the TCM with the new data file stored on the TIS web site for all pressure regulating solenoid valves that were replaced.

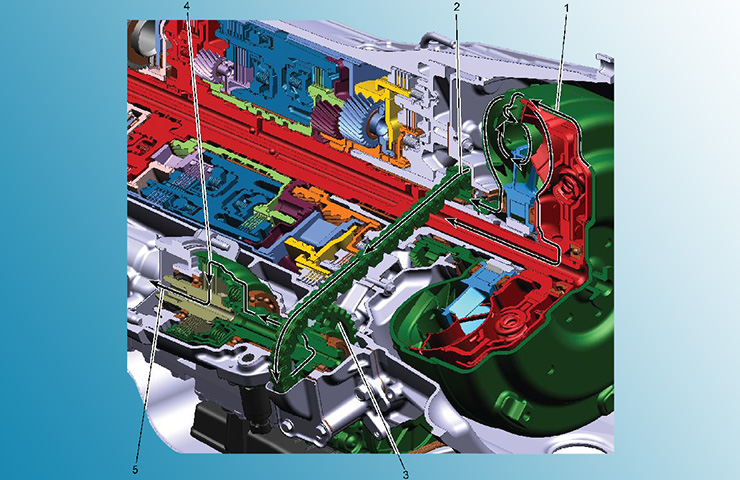

Power Take-Off

The available all-new factory-integrated, engine-driven Power Take-Off (PTO) eliminates the need for an aftermarket unit. Exclusively offered with the 10-speed transmission (RPO MGU) on select diesel models, it’s the first fully integrated PTO system in the HD truck segment, with the PTO’s drive gear operated via chain to direct engine power. (Fig. 17) And because it is engine-driven rather than turbine-driven, the PTO can be used while the vehicle is idling. A button inside the cab enables the PTO, and a mode selector allows adjustment of load and torque output.

Fig. 17

Fig. 17

– Thanks to Kevin Minor and Sherman Dixon

Does the 10L1000 transmission have an external file like the L1000 ( 6 speed)

Does the bolt pattern the same as it predecessor?

Can you provide specific clutch applications for each range?