When testing or charging a 12V battery in a vehicle that is in for service or is part of the dealership’s inventory, the EL-50313 Midtronics GR8 Battery Tester/Charger or EL-52800 Diagnostic Charge Battery Station (DCBS) (Fig. 1) should be used in order to provide an accurate diagnosis about the battery’s state of health. Updated guidelines have been released recently in Bulletin #20-NA-132 that outline the testing process and warranty claims.

Fig. 1

Fig. 1

Warranty Codes

During diagnosis of a battery or performing battery maintenance on new vehicles in dealership inventory, the warranty code generated by the GR8 or DCBS captures critical information about the battery’s condition.

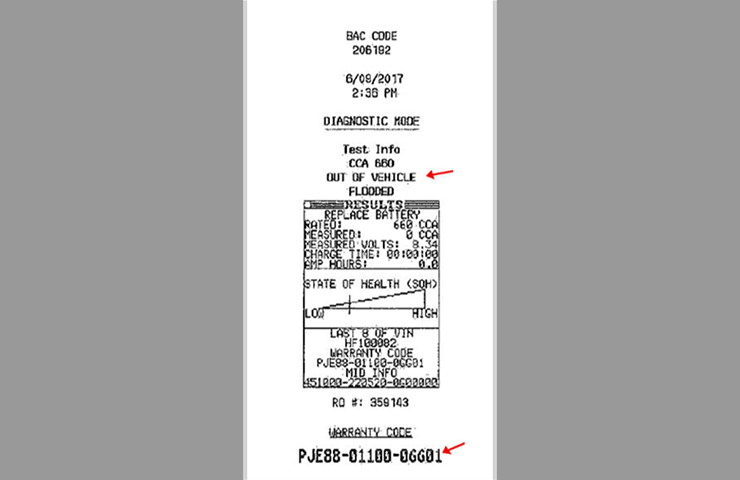

TIP: The GR8 only generates a warranty code when the battery test is set up for Diagnostic Mode and Out of Vehicle.

A warranty code from the GR8 (Fig. 2) or DCBS (Fig. 3) is required for all warranty claims for battery replacement to help analyze battery failures and improve product quality. The Warranty Support Center validates all warranty codes entered in the Battery Tester Code field for batteries replaced under warranty. Warranty claims for battery replacements with invalid test codes, incorrect test set-up, or the wrong battery type will not be authorized.

Fig. 2

Fig. 2

Fig. 3

Fig. 3

Battery Type and CCA Rating

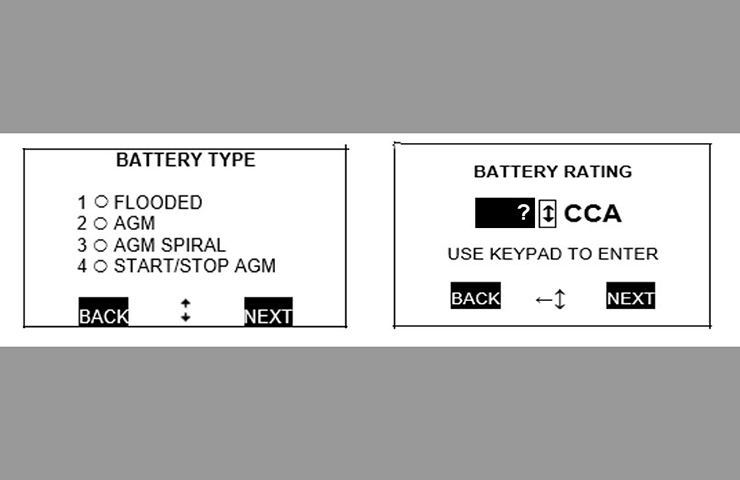

When testing 12V batteries, be sure to follow the diagnostic procedures in the appropriate Service Information. Always disconnect the battery from the vehicle and select the proper Battery Type and CCA Rating (Cold Cranking Amps) for the battery being tested. (Fig. 4, GR8 shown)

Fig. 4

Fig. 4

Selecting the incorrect Battery Type or CCA Rating may result in battery damage or a “Battery is bad” result on a good battery, leading to a good battery being replaced unnecessarily

TIP: Battery Type and CCA Rating should be identified from the OEM battery label in the vehicle. Do not use IVH RPO data for CCA ratings as select vehicles display a metric reading where the battery tester requires the entry of the standard CCA rating.

When using the DCBS, avoid errors and improper test setup by using the VIN scan feature to accurately load the VIN, Battery Type and CCA Rating for the vehicle.

On vehicles with two batteries, including vehicles with auxiliary batteries, each battery must be electrically isolated and charged individually.

Battery Testing

Batteries that are deeply discharged will take an extended time to recharge. Also, batteries that are cold (below freezing) are resistant to charging and can falsely fail testing. Batteries that are cold and deeply discharged must first be warmed to above 4°C (40°F) prior to testing and charging.

Using the GR8 – Select “Charging,” “Diagnostic” when setting up the test. Enter the correct Battery Type (Flooded, AGM, or Start/Stop AGM) and rated CCA (both from the battery label). Use the Out of Vehicle test (battery disconnected with test equipment connected directly to the posts) for each battery when testing a vehicle with dual batteries.

Using the DCBS – Select “Diagnostic” and “Trolley” when setting up the test. Scan the VIN and verify the battery selection is correct, or manually select the correct Battery Type (Flooded or AGM) and rated CCA (both from the battery label).

TIP: The Battery Type selection of Start/Stop AGM is only for testing the small secondary “AUX12” battery on some vehicles equipped with Auto Stop/Start (RPO KL9), not all vehicles with the automatic engine stop/start system. Do not select Start/Stop AGM for vehicles equipped with diesel engines or the Dual Battery Option (RPOs K4B, TP2).

Tool Software Updates

Battery testers require periodic software updates. The latest software release for the GR8 is available through GlobalConnect by selecting “Essential Tools – Software Updates” on the Service page of the App Center.

To update the DCBS, go to www.e-xteq.com and select the Download option on the top menu bar. Once accessed, click Download Optimus and follow the prompts. If Optimus is already loaded on the PC, access it and complete the update.

TIP: Be sure the GR8 or DCBS software is up to date. Only warranty codes generated by the GR8 or DCBS using current software are valid for batteries replaced under warranty. Warranty Codes generated by past versions of software or the old hand-held tester are not valid.

PDI Mode

When a new vehicle is received at the dealership, the battery must be checked as part of the Pre-Delivery Inspection (PDI). The GR8 and DCBS have a charge algorithm identified on the tool as PDI Mode. In this mode, the battery condition is checked and then a fast charge is applied to the battery. PDI mode is designed to apply as much charge as safely possible in 20 minutes. To get a complete charge, it’s recommended to continue the battery charge in Top Off mode.

PDI Mode generates a printout without a warranty code that must be kept with the vehicle file as proof of maintenance. Checking the battery using PDI Mode also must be done at subsequent 30-day intervals while in dealership inventory and at the point of sale.

Vehicles with Stop/Start auxiliary batteries must be charged separately from the main battery while in dealership inventory storage. The Auxiliary battery is not connected in a manner that will allow both batteries to be charged at the same time, so it must be charged individually, which will result in two printouts.

If a new vehicle arrives from transportation at the dealership with a defective battery, it must still be properly tested and a valid warranty code must be entered on the transaction. The transaction must be submitted within one week of vehicle arrival at the dealership.

Battery Replacement

The warranty code generated by the GR8 or DCBS that is displayed on the printout must be entered in the required Battery Tester Code field when submitting a battery replacement transaction. Technicians must attach the printout with a Replace Battery (GR8) or Battery is Bad (DCBS) decision on the repair order (job card). A copy of the printout must be returned with the paperwork for each battery returned to the Warranty Support Center.

If a battery is replaced under warranty and it is found that test records indicate that the Battery Type or CCA Rating entered in the GR8 or DCBS does not match that of the battery replaced, the transaction will be subject to chargeback.

Proactive Alert SAC001

On connected vehicles, GM is able to evaluate the condition of the battery and report the state of health to the customer through the OnStar Diagnostics Report and/or to the dealership under Alerts in Service Workbench or the Techline Connect dashboard. Technicians may also validate alerts by using a scan tool through Vehicle Diagnostics/Vehicle Proactive Alerts.

If the Proactive Alert indicator is red, SAC001 is present, which indicates a shorted cell and the battery should be replaced. Batteries replaced due to Proactive Alert Identifier SAC001 do not require battery testing. In these cases, SAC001 should be entered into the Battery Tester Code field. Diagnostic Add Time is ineligible in these cases and must not be claimed on the transaction. SAC001 is the only Proactive Alert Identifier that does not require diagnosis.

For additional information on proper 12V battery testing/charging, refer to the following resources:

- “Battery Inspection/Test” diagnostic information in the applicable Service Information

- “Battery Charging” diagnostic information in the applicable Service Information

- Bulletin 20-NA-132: Warranty Administration – Battery Testing and Warranty Replacement Requirements

- Course 10220.09V September 2020 Emerging Issues Seminar (Back to Basics Video segment) for U.S. dealers or the October 2020 TAC TALK for dealers in Canada

– Thanks to Troy Henige and Brett Holsworth

Waiting on this tool.