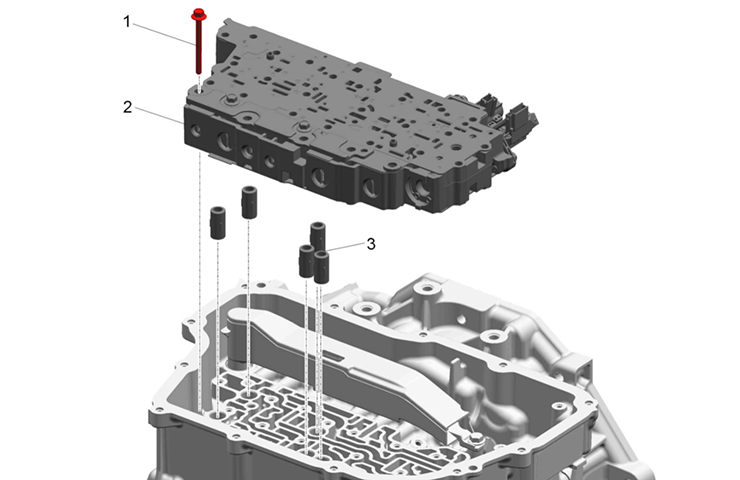

When diagnosing low-mileage 2020 Regal, Equinox; 2020-2022 Encore GX, Envision, XT4, XT5, XT6, Blazer, Malibu, Acadia, Terrain; and 2021-2022 Trailblazer models equipped with the 9T45 (RPO M3F, M3U), 9T50 (RPO M3D, M3E, M3H) or 9T60 (RPO M3G, M3T) automatic transmission, there are several service procedures to follow to ensure repairs are completed properly. These low mileage vehicles (less than 12,000 miles or 19,000 km) may have DTCs set that are related to the control solenoid and valves. (Fig. 13)

Fig. 13

Fig. 13

Refer to these bulletins and PIs for additional information before proceeding with the following service procedures:

- #18-NA-359: Information on Flashing D in PRNDL and/or Transmission Slip/Flare on 1-2 Upshift with Zero to Very Light Throttle Input

- #21-NA-038: Humming Noise Heard Coming from Front End of Vehicle When Driving at Highway Speeds (Blazer)

- #19-NA-023: High Pitch Whine Noise Heard at 32-56 km/h (20-35 mph) in Any Gear under Light to Moderate Acceleration (Equinox, Terrain)

- #20-NA-165: Flutter or Boom Noise at 1200 RPM – Service Calibration (Trailblazer, Encore GX)

- #PIT5778A: Vibration or Boom at 1300 RPM (Equinox, Terrain)

- #PIP5697B: DTC P0747 Setting at Engine Start-Up When the Transmission is in Park

- PIT5825B: Vibration-Type Noise Heard at Highway Speeds or with Engine Speed at 1,300-1,500 RPM (XT5, XT6, Blazer, Acadia)

For complete details on the following diagnostic steps, refer to Bulletin #21-NA-169.

Step 1 – DTCs

Check all modules for DTCs. Record all current DTCs or DTCs set in History along with the control module on the repair order.

Step 2 – Fluid Level and Condition Check

Ensure the transmission has enough fluid in it to safely start the vehicle without damaging the transmission. With the vehicle off and the transmission fluid temperature at approximately 20–25°C (68–77°F), there should be enough fluid to drain out of the fluid level hole. This will ensure that there is enough fluid in the sump to fill the components once the vehicle is started.

To check for the proper fluid level, the transmission fluid temperature (TFT) must be 85–95°C (185–203°F). If the TFT is not at this temperature, operate the vehicle or allow the fluid to cool as required. Setting the fluid level with a TFT outside this temperature range will result an under- or over-filled transmission. An under-filled transmission will cause premature component wear or damage. An over-filled transmission will cause fluid to discharge out the vent tube, fluid foaming, or pump cavitation.

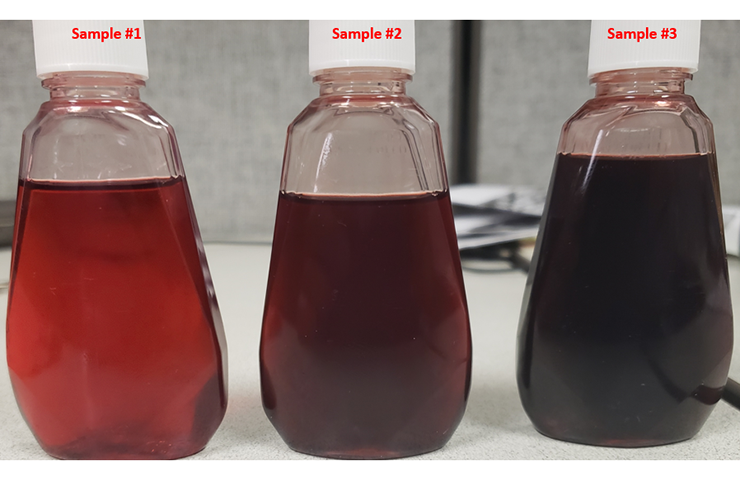

Also check the condition of the fluid. It should be red or brown and transparent enough so that objects or writing can be seen through it. (Fig. 14)

Fig. 14

Fig. 14

The fluid should not have an odor of burnt fluid. Dark fluid or a burnt odor would indicate clutch damage has occurred internally in the transmission.

In addition, inspect the fluid for excessive metal particles or debris. A small amount of friction material or metal from the manufacturing process – observed as fine silver streaks – are normal conditions.

Step 3 – Line Pressure Check

To access the transmission line pressure test hole plug, it may be necessary to remove or disconnect some components. Use the GE-21867 Pressure Gauge to check the transmission fluid pressure with the engine running. (Fig. 15)

Fig. 15

Fig. 15

If pressure is below 50 psi, follow the procedure for Fluid Pressure High or Low in the appropriate Service Information. If pressure is above 50 psi, continue diagnosis with a road test.

Step 4 – Road Test

Be sure to inspect all electronic transmission components for proper operation before the road test. If these components are not checked, a simple electronic condition may be misdiagnosed.

Check the garage shifts and verify the gear engagements are immediate (less than two seconds to complete if transmission fluid temperature is above 20°C (68°F) and not harsh or delayed. Possible causes of harsh engagement include high engine idle speed, a default condition caused by certain DTCs that result in maximum line pressure to prevent clutch slippage, or incomplete adapting or incorrect adapting. Delayed engagement may be caused by low idle speed, low fluid level, cold TFT, a selector linkage condition, or incomplete or incorrect adapting.

Next, with the vehicle in Drive, monitor scan tool parameters while checking:

- Upshifts

- Part-throttle step-in downshifts

- Coasting downshifts

- Reverse

Note any harsh, soft or delayed shifts or slipping as well as any noise or vibration. Follow the appropriate Service Information for any detected conditions.

TIP: If completion of the road tests are inconclusive to isolate if any transmission shifting concerns are related to internal transmission or input/command issues, use the control function feature in GDS2 to command all shifts. When using GDS2 to command shifts and the transmission shifts into each range, the concern is generally an input/command concern, and not an internal transmission concern. If ranges are not completed when using GDS2 to command, then the concern may be an internal transmission concern.

Step 5 – DTCs

Record any current DTCs or DTCs that reset during the road test on the repair order.

Based on the transmission control solenoid valve DTCs that set, along with the condition of the transmission fluid, it may be necessary to inspect for damage to the clutch packs. However, some DTCs may only require the solenoid body and valve body be replaced, while others may require replacing only the solenoid body or valve body.

Refer to Bulletin #21-NA-169 for a complete list of possible DTCs and the related repairs. Also refer to the bulletin for additional details for each service procedure step.

– Thanks to Mark Kevnick

issue of proper diagnosis on all 6T transmission is still on clear to some of our Technicians.

We need your support and advice please. On the area of component handling.