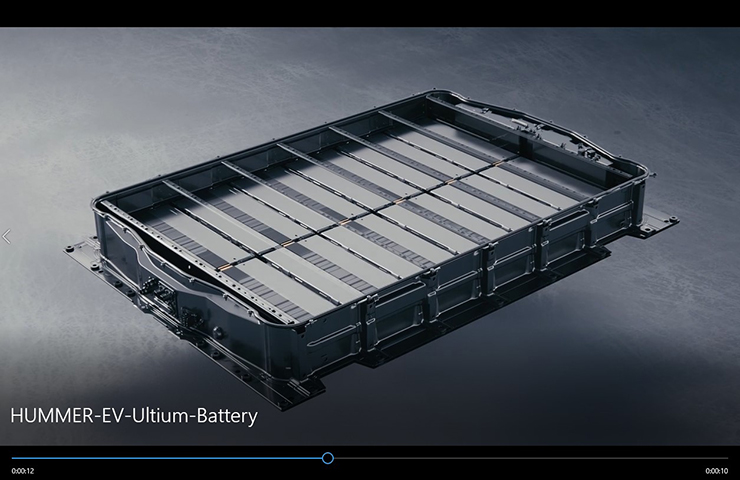

The all-new 2022 GMC HUMMER EV Edition 1 Pickup is powered by an Ultium 24-module battery system that boasts a GM-estimated 1,000 horsepower and a combined axle torque of 11,500 lb.-ft. while providing a range of 329 miles (529 km) on a full charge.1 The Ultium architecture provides the framework to integrate a number of advanced technologies that make the HUMMER EV a true supertruck. (Fig. 12)

Fig. 12

Fig. 12

Battery Architecture

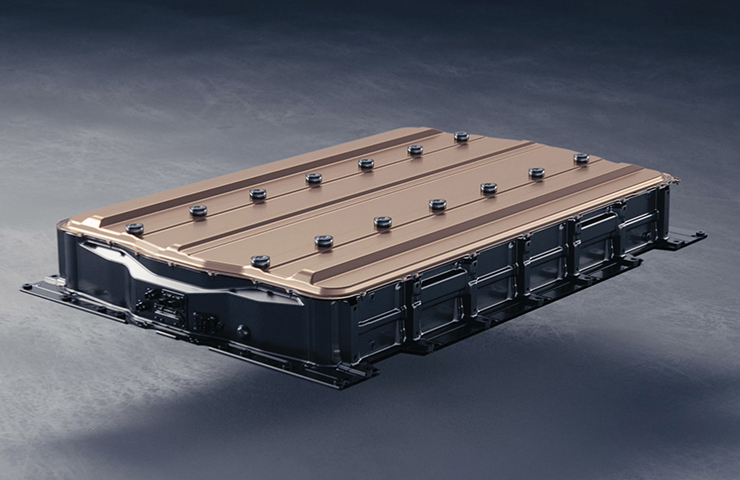

The Ultium high-voltage battery pack on the HUMMER EV Edition 1 Pickup features large-format, pouch-style lithium-ion cells, which can be stacked vertically or horizontally inside the battery pack, depending on packaging requirements. The large-scale, high-energy Ultium battery cells are stacked vertically in two layers and mounted beneath the passenger compartment in the HUMMER EV Pickup. (Fig. 13)

Fig. 13

Fig. 13

The unique nickel, cobalt, manganese, aluminum (NCMA) cell chemistry of the Ultium batteries use 70% less cobalt than GM’s previous generation of EVs, resulting in some of the lowest cobalt — a rare and costly material — content of any large-format pouch cells. The cells are configured in three parallel strings of eight. The cell groups are electrically joined in series to form the Cell Module Assembly (CMA), also known as a high-voltage battery section.

The pack contains 24 CMAs. Each CMA is identical, although uniquely serialized, and contains a non-serviceable K112 EV Battery Interface Control Module with a wireless transmitter/receiver. These smart modules monitor temperature, current and voltage to maintain balance within the truck’s battery cell groups for optimal performance and battery longevity.

Each K112 EV Battery Interface Control Module communicates wirelessly with the K291 EV Battery Pack Communication Module, which is also located within the battery pack. The K291 EV Battery Pack Communication Module in turn communicates with the vehicle-mounted K16A Battery Energy Control Module (BECM) via wired communication circuits. The K16A BECM is the host controller for all battery diagnostics and system status.

The Ultium batteries are cooled and heated with a 50/50 mixture of DEX-COOL coolant and de-ionized water. Each CMA and the A28 EV Battery Disconnect Relay assembly contain internal coolant passages. A refrigerant/coolant heat exchanger (chiller) and the G1HV Air Conditioning with Motor Compressor cools down the high-voltage battery.

Charging Capabilities

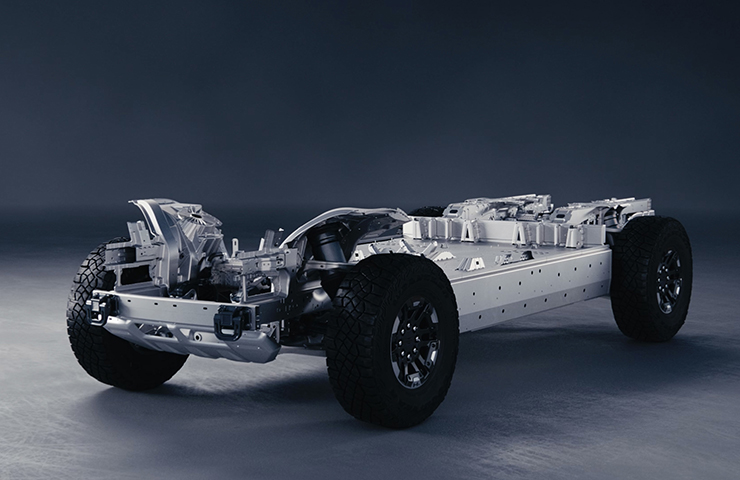

The two layers of battery cell modules combine to produce a pack with approximately 200 kWh of available energy. The CMAs in each layer are configured in series, essentially operating like two battery packs in one assembly. (Fig. 14) The total voltage per layer is about 400V.

Under normal operating conditions, these two layers operate electrically in parallel with each other. If conditions allow, the high voltage contactors can be configured so that each layer is wired in series to facilitate 800V charging. As a result, the flexible, high-voltage architecture enables 800-volt DC fast charging using the industry’s fastest 350-kilowatt DC fast chargers available at public locations.2

The charging system also is designed to support legacy 400-volt charging infrastructure, without the need for a converter box or other accessories, allowing the HUMMER EV to use a variety of charging stations. The vehicle’s charging hardware is complemented by in-vehicle and available smartphone apps that help customers find available charging locations while also preconditioning the battery to the proper temperature for the most efficient charging session.

Charging Levels

The dual-level charge cord, provided with the vehicle, includes two types of household electrical plugs: a standard 120V receptacle for Level 1 charging and a 220–240V receptacle for Level 2 charging. Level 2 charging using a 240V NEMA 14-50 outlet (40 amp breaker) provides approximately 10 miles (16 km) per hour of charge.2 Battery charge level is indicated by the vehicle’s state-of-the-art lighting. (Fig. 15)

Fig. 15

Fig. 15

Level 2 charging using an optional Level 2 240V (60 amp breaker) home charging station or a public station provides approximately 16 miles (26 km) per hour of charge. 2

Level 3 fast charging, or DC Fast Charging, (up to 800V/350kW) uses DC current supplied directly to the drive motor battery. Fast charging capability provides approximately 100 miles (160 km) in 12 minutes (peak charging). Level 3 chargers are typically found only in a commercial/public location. 2

Regen on Demand

With Regen on Demand and One-Pedal Driving — both driver-controlled braking features —the kinetic energy of the truck’s forward momentum can be converted into electricity to be stored in the Hybrid/EV Battery Pack, further optimizing the driving range.

While pulling the steering wheel paddle, Regen on Demand can slow the vehicle to a full stop without pressing the brake pedal. (Fig. 16) Similarly, One-Pedal Driving can slow the vehicle to a full stop using the accelerator pedal to provide very fine control. One-Pedal Driving can be configured with multiple levels to match the driver’s preference.

Fig. 16

Fig. 16

For more information about the new GMC HUMMER EV, refer to Bulletin #21-NA-295.

– Thanks to Mark Shearer and David Rainey

1Actual range will vary based on several factors, including temperature, terrain, battery age, loading, use and maintenance.

2Actual charge times will vary based on battery starting state of charge, battery condition, output of charger, vehicle settings and outside temperature.