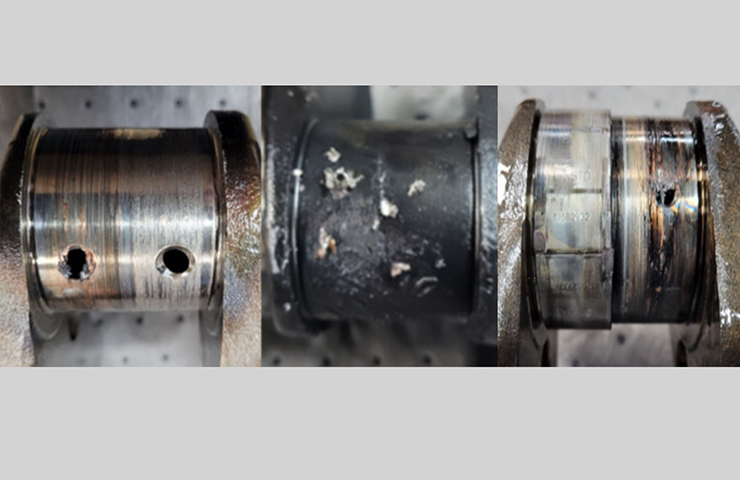

A no crank condition may be found on some 2019-2023 Silverado, Sierra; 2021-2023 Tahoe, Suburban, Yukon and Escalade models equipped with the 6.2L V8 engine (RPO L87). The no crank condition may be due to a seized engine with an open starter fuse. Various engine sounds, such as a thumping, knocking or rattling, may be present. These conditions may be the result of crankshaft bearing failure. (Fig. 5)

Fig. 5

Fig. 5

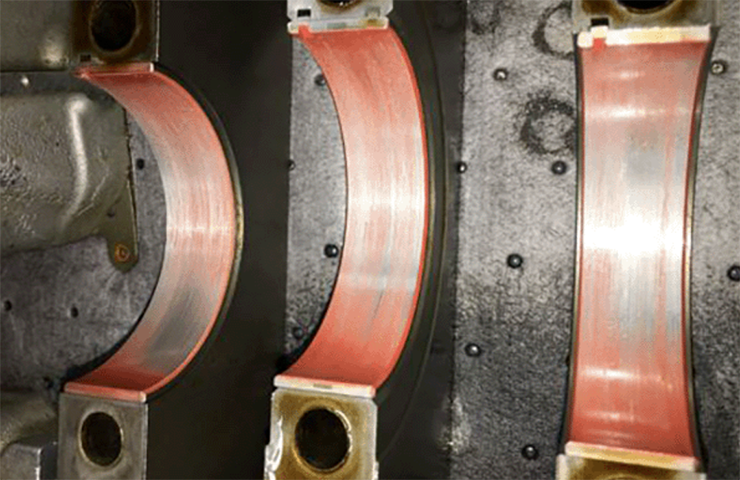

In cases involving suspected bearing failure, first check the engine oil and filter for excessive metal debris and bearing material. (Fig. 6) Inspecting the oil filter for excessive debris and damaged pleats can be a helpful indicator of the amount of material that has been displaced through the engine and lubrication circuits.

Fig. 6

Fig. 6

If bearing material is identified, remove the engine oil pan and inspect the crankshaft rod and main bearings for any damage. Component replacement or, depending on the extent of damage, engine replacement may be necessary.

Engine Component Replacement Guidelines

The amount of bearing damage determines if the engine should be replaced. Bulletin #18-NA-073: Repair Guidelines for Engine Component Wear provides details about wear characteristics of engine components and replacing worn components, including the crankshaft main bearings and journals. Engine assembly replacement should be based on the extent of the damage to individual components. (Fig. 7)

Fig. 7

Fig. 7

Oil Cooler Components

If there is crankshaft main bearing failure, it may be necessary to also replace the oil cooler, oil cooler lines and oil tank, if equipped, along with the damaged engine components. Refer to Bulletin #22-NA-074 for more information about engine repairs after crankshaft main bearing damage.

If the main bearing debris is sent through the oil galleries and other components that are in the lubrication circuit, which are very difficult to completely clean, it could lead to additional damage when installed on a new engine. When there is extensive damage, oil cooler, oil cooler line and oil tank replacement ensures all debris is completely removed and that any bearing failure debris is not transferred into the new service engine.

For additional information, refer to #PIP5900.

– Thanks to Bryan Salisbury

If it has been found there is damage to the crankshaft bearings, please follow the latest versions of Technical Service Bulletins 22-NA-074 and 18-NA-073 for further repair direction.

Show pictures showing examples of damage requiring replacement. Large amount of bearing debris through all of the block oil galleries and passages including overheated and blued main caps should be cause for replacement especially at the labour times GM expects the remaining techs that haven’t left to go to truck and coach, transit, etc to repair them at.