Talc powder applied inside the rubber boot of the ignition coil may be causing a rough running engine or misfire condition on some 2019 Envision, Regal, ATS, CTS, Camaro, and Traverse models equipped with the 2.0L 4-cylinder engine (RPO LTG). The Check Engine MIL also may be illuminated along with DTC P0300 (Engine Misfire Detected) set in the Engine Control Module (ECM).

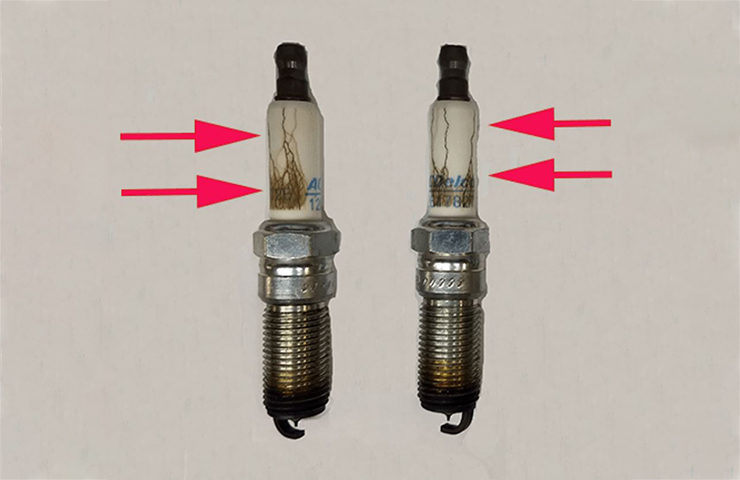

Talc powder was applied to prevent the rubber boot from sticking to the porcelain insulator of the spark plug. However, the talc powder has a lower insulating strength than dielectric grease, which may lead to possible arcing, eventual carbon tracking (Fig. 1) and, ultimately, a misfire condition. A prolonged misfire condition can result in piston damage.

Fig. 1

Fig. 1

Spark Plug Inspection

If a misfire condition is present on the 2.0L engine, inspect all spark plugs for signs of carbon tracking and inspect the pistons and cylinder walls for damage.

In addition, perform a cylinder leak down test on the affected cylinder or cylinders to check that the misfire is not caused by piston leakage and leakage into the crankcase. Refer to Cylinder Leakage Test in the appropriate Service Information.

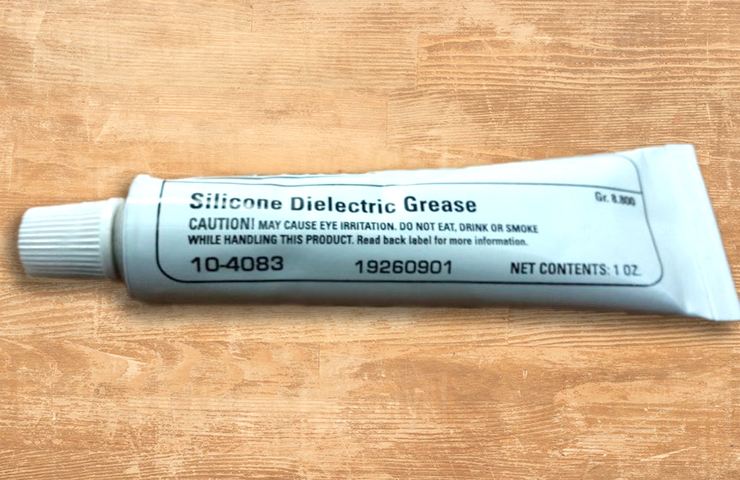

If there is no high cylinder leakage found, replace all four spark plugs and all four coils if any carbon tracking is seen on any of the spark plugs. All spark plug boots also will require an application of Molykote G-5008 Dielectric Grease. (Fig. 2)

TIP: All the ignition coil boots will require proper application of dielectric grease. Only use the green color dielectric grease. Do Not use the white/clear dielectric grease as it will not work for this application. Apply it correctly or the engine conditions/damage may re-occur.

Fig. 2

Fig. 2

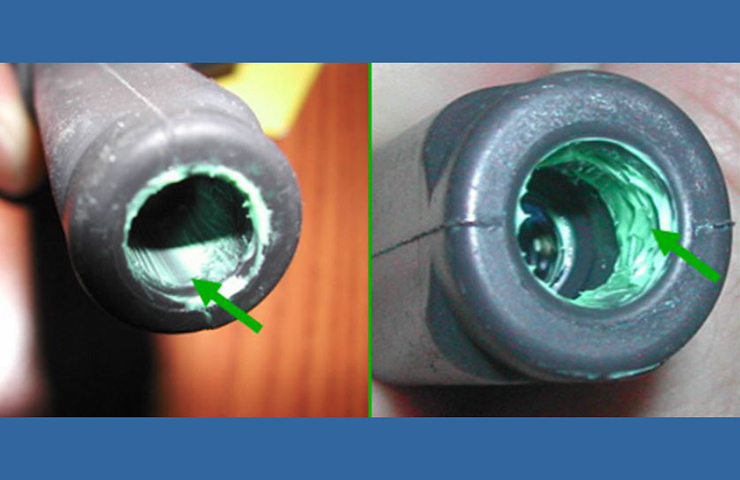

Inspect all the ignition coils and apply additional dielectric grease if required. Using an applicator stick or equivalent, apply a thin coating of grease in the rubber boot of the coil, up to a depth of 15 mm. (Fig. 3) Remove any extra grease from around the end of the boot. Do not use an excessive amount of grease in the boot.

Fig. 3

Fig. 3

The dielectric grease should be applied evenly inside the boot, from the end of the terminal to the edge of the boot. (Fig. 4)

Fig. 4

Fig. 4

TIP: Be sure to only use the specified dielectric grease (U.S. – 19260901; Canada – 19260902) and apply it correctly or the engine conditions/damage may reoccur.

Piston and Engine Cylinder Inspection

When inspecting the condition of all cylinder walls, there may be some light vertical marks visible on the cylinder wall. In these areas, check that the cross-hatch marks are still visible in the marked area. If the cross-hatch marks are visible, the cylinder surface has not been compromised and the engine block can be used. A good test is to run a fingernail across the cylinder wall. If you catch your nail on anything on the cylinder wall, the engine assembly must be replaced.

If any of the cylinder walls are damaged, replace the engine assembly (engine comes with spark plugs), all four ignition coils (apply dielectric grease to the spark plug boots as previously described), the fuel injector of the cylinder(s) that had damaged pistons, and other components necessary when an engine assembly is installed.

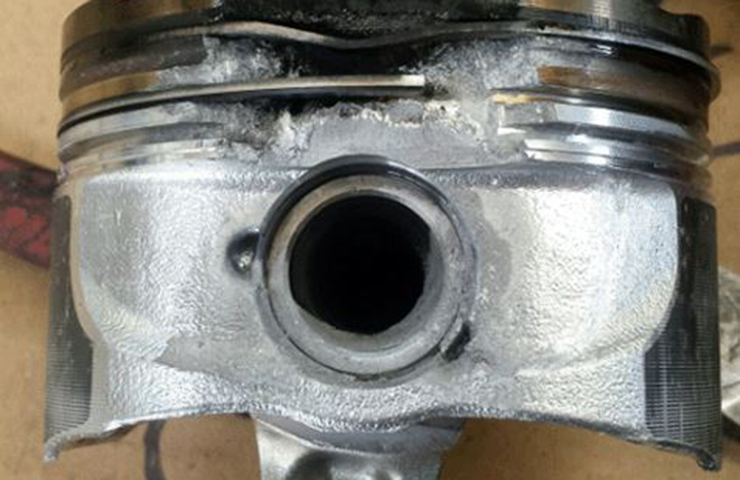

If the cylinder walls are not damaged, remove the pistons and inspect for a fractured piston between the top and second rings. (Fig. 5)

Fig. 5

Fig. 5

If the cylinder walls are not damaged and one or more of the pistons are found fractured, replace all four spark plugs, all four ignition coils (apply dielectric grease to the spark plug boots as previously described), the fuel injector of the cylinder(s) that had damaged pistons, all four piston kits, all ring sets for all four pistons, all rod bearings, all four connecting rod assemblies, and other components necessary when pistons are replaced.

When installing the pistons, use the J-43953 tapered ring compressor special tool. Use care when installing the piston assemblies into the cylinder so the rings are not damaged.

Refer to Bulletin #19-NA-246 for additional information and part numbers.

– Thanks to David Rutkowski and Javier Hinojos

Updated January 9, 2020