In order to accurately diagnose a battery’s state of health from a vehicle in for service or that is part of the dealership’s inventory, the EL-52800 Diagnostic Charge Battery Station (DCBS) should be used. (Fig. 4) The DCBS offers comprehensive battery diagnostic services and testing for lead acid, Absorbent Glass Mat (AGM) and Enhanced Flooded Battery (EFB) batteries and is the recommended and approved tool for diagnosing warranty battery replacement.

Fig. 4

Fig. 4

With the enhanced testing speed and accuracy of the DCBS, as well as the ability to recover more batteries in the charging process, the Midtronics GR8 battery tester is no longer recommended for battery testing, but will be accepted until every GM dealership has the DCBS.

Essential Equipment

Effective January 1, 2024, the DCBS will become Essential Equipment for all GM dealerships. GM will arrange to ship one DCBS to those dealerships that do not have a DCBS prior to 2024.

Shipments will begin in May and will continue throughout the year for Tier 1 and Tier 2 dealerships. Remaining dealerships can expect shipments by the end of the 3rd quarter of 2023. The timing of shipments may change based on global supply chain constraints and availability.

Warranty Requirements

Beginning January 1, 2024, the Midtronics GR8 will no longer be acceptable equipment for warranty transactions. The DCBS will be the only approved equipment for diagnosing batteries under warranty. The DCBS Warranty Claim Code and test result printout attachment will be the only acceptable supporting documentation for warranty battery replacement transactions.

The warranty code displayed on the printout (Fig. 5) must be entered in the required Battery Tester Code field when submitting a battery replacement transaction. Technicians must attach the printout to the repair order (job card) when there is a Battery is Bad (DCBS) or Replace Battery (GR8) determination. A copy of the printout must be returned with the paperwork for each battery returned to the Warranty Parts Center.

Fig. 5

Fig. 5

Battery Testing

Bulletin #20-NA-132 outlines the testing process and warranty replacement requirements that all GM dealerships must follow.

The DCBS features a hand-held diagnostic remote that can read 1D barcodes and 2D QR codes that, along with an integrated GM vehicle database with battery specifications, offers quick vehicle identification of GM vehicles to help speed up the diagnostic process. The GM database also eliminates the need to find the battery rating on the original battery label during testing. If the original battery has been replaced, the battery specifications from the battery label installed in the vehicle should be used.

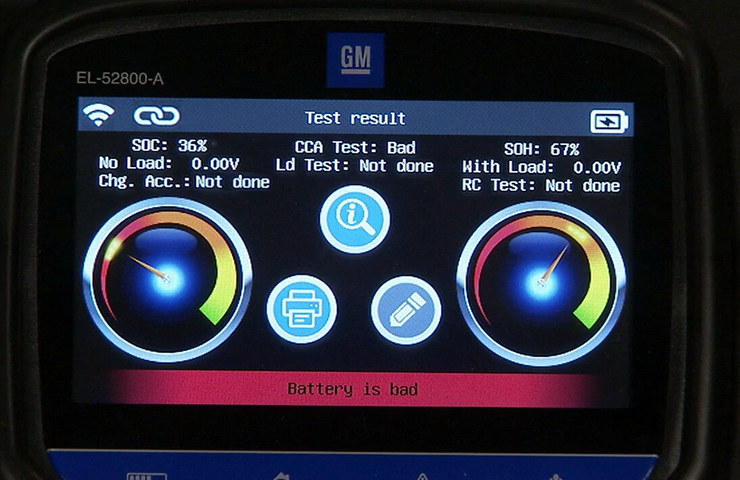

On-screen test results using the DCBS will show “Battery is good” if the battery has a good state of health or “Battery is bad” if the battery needs to be replaced. (Fig. 6) The tool will ask for the RO along with the VIN and BAC if not already entered. It will then print a warranty code if the test was run using the trolley. A warranty code will not be generated when a battery test is done with the remote only.

Fig. 6

Fig. 6

Software Updates

When dealerships receive the new DCBS unit, it is critical that the Optimus software, which is included with the DCBS, be downloaded. The Optimus site is used to store all the testing records (up to 65,000) that are performed at the dealership and enables dealerships to view past test records and retrieve warranty codes. In addition, all DCBS software updates that are released to keep the DCBS operating with the latest vehicle information and product enhancements will only be delivered to the handheld diagnostic remote through the Optimus program. All DCBS updates are free to dealerships.

Dealerships with any questions regarding the Optimus platform, software updates or general product inquiries should contact the customer help desk at 1-877-453-3265.

For additional information, refer to GlobalConnect message GCUS-9-12992 (U.S. only).

– Thanks to Zach Winters and Patti Marino

The date of requirement of Dealerships to have the EL-52800 is only weeks away, it is November 28th 2023, and we still have not received one, GM Special tools does not even list this tool, will someone please reply as to whom we can contact to resolve this issue.

SINCE WE AQUIRED THE DCBS WE HAVE HAD SERIOUS PRINTER PROBLEMS. ALOT OF TIMES WHEN PRINTING OUT A BATTERY SLIP IT COMES OUT LOOKING LIKE CHINESE AND IS ABOUT 2-3 FEET LONG.

Thank you for your comments. We are sorry to hear that you have experienced loss of connection while using the wireless connection feature. Unfortunately, we have received feedback that external interference can cause signal interruption between the remote and trolley, similar to other electronic equipment in the service bay operating on Wi-Fi. However, the DCBS does come equipped with a physical connection, which provides a 100% reliable connection between the remote and trolley components. Additionally, you do not lose any of the wireless functionality or benefits when using the physical connection, as all pre-test actions (VIN scan, battery temperature reading, RO scan) can all be done with the remote while disconnected from the ethernet cable. When the remote is placed in the docking station to start the test (which is required, even when connected wirelessly), that is when the physical connection with the ethernet cable to the trolley is made. With the physical connection, there can be no signal loss (unless the technician disconnects during the test), meaning no stoppage mid charge or loss of time during performance of job. If you have any questions or would like further support, please contact E-XTEQ at (877) 453-3265 or support.usa@e-xteq.com and we will be pleased to assist you. Additional user resources at https://e-xteq.com/customer-documents-gm/ .

The DCBS is NOT A GOOD option. the GR8 works flawless and now we have this pile. please go to new version of GR8. always connection issues. stops working mid charge. I dont have the time to waste on this.

Thanks for your feedback. A representative of GMDE will contact you to gather more information.

BY COMPARISON, THE GR8 IS A ROCK-SOLID MACHINE. DCBS IS TOO SMART TO TEST OR CHARGE BATTERIES THAT HAVE BEEN RUN PRETTY LOW. WON’T LET ATTEMPT TO BRING THEM BACK UP. THEY LOSE WIFI BETWEEN THE TROLLEY AND KEYPAD ALL THE TIME. ULTIMATELY END UP TAKING LONGER TO USE….

Yeah; we have replaced ours as well , they are very fragile. And with our current crop of Young techs being hard on any tool in the shop…. currently we are having issues with DCBS failing far to many batteries as “Sulfated” ; Brand new vehicles during PDI … Just updated the base unit as well as the hand held unit, still failing Brang new cars during PDI as “Sulfated” … terminals disconnected and clamping directly at Posts

I would just like to get some feed back from the guys that have been using this. We have had ours replaced 2 times. You dont know if the printer is going to work. sometimes the charge before the test will take forever. We left it on a battery for 98min. then it passed. We let it set for a while to cool off tested it again and it failed. I would just like to know if any one else is having issues and what they think compared to the GR8. Thanks

Having dealt with a DCBS for about 2 years, I have a question. Will there be a redesigned clamp at some point in the future? The standard clamps are extremely fragile and begin cracking from the first use. We have ordered replacement cables with clamps on them but they also break after a couple dozen cycles of opening.