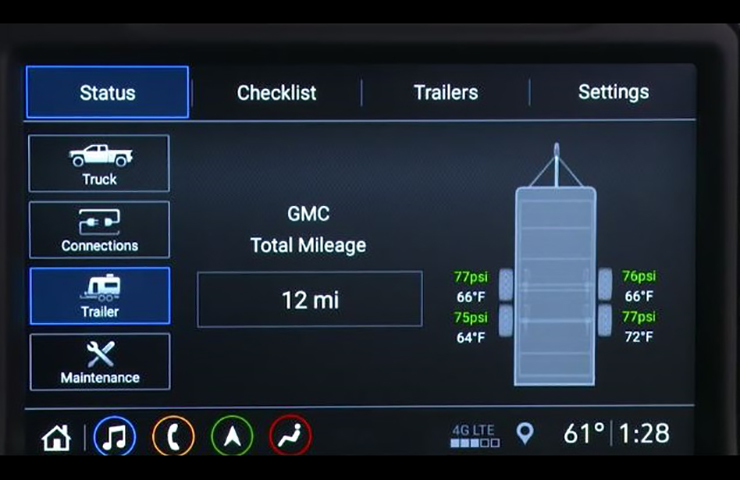

The in-vehicle trailering app (RPO U1D) included with the Advanced Trailering System available on the 2019-2021 Silverado 1500 and 2020-2021 Silverado 2500HD/3500HD and the ProGrade Trailering System available on the 2019-2021 Sierra 1500 and 2020-2021 Sierra 2500HD/3500HD incorporates the functions of several vehicle systems in order to provide trailer lighting diagnostics, trailer tire pressure/temperature monitoring and trailer braking with an Integrated Trailer Brake Controller. (Fig. 1)

Fig. 1

Fig. 1

The trailering system consists of the following systems:

- Trailer lighting

- Trailer brakes

- Trailer battery charging system

- Trailer detection

- Trailer tire pressure monitoring system

- Trailer theft detection

TIP: When a trailer is detected on a vehicle equipped with Side Blind Zone Detection, Rear Park Assist, and/or Rear Cross Traffic Alert, the vehicle will automatically turn these features off in order to prevent false detections due to the trailer obstructing the view of the sensors.

Trailer Detection

The K68 Trailer Lighting Control Module constantly monitors for trailer connection status through the lighting circuits of the trailer. The total combined park lamps and stop/turn signal lamps of the trailer must draw a minimum of 55mA to be detected by the Trailer Lighting Control Module. With the key off, the Trailer Lighting Control Module will periodically pulse the lighting circuits of the trailer to verify it is still connected. Depending on the configuration of the trailer lights, the trailer lights may periodically flash as part of the trailer connection detection or theft deterrent functions. These flashes may be more visible in dark ambient light environments and correspond to when the Trailer Lighting Control Module pulses the lighting circuits to ensure the trailer is still connected.

When a trailer is connected, the trailering app asks the user to set up a trailer prolife. The Trailer Detection Alert setting must be enabled in the trailering app for the alert to display when a trailer is connected. If a trailer is disconnected with the ignition on, the vehicle will display multiple trailer lighting messages.

Some trailers use a trailer-mounted control module to control the trailer lighting, which may require a B+ circuit to the trailer connector to control trailer lighting. These trailers may not be detected by the K68 Trailer Lighting Control Module and may require an additional trailer adaptor for the vehicle to recognize that the trailer is connected, such as load resistors added in parallel to the detectable lighting circuits of the trailer to increase current draw or rewiring the trailer to eliminate the trailer-mounted control module so the circuits are wired directly to the trailer lamps.

Trailer Lighting

For lighting operation, the K68 Trailer Lighting Control Module receives serial data messages from the Body Control Module (BCM) and/or Exterior Light Module (ELM), indicating which lamps have been activated on the vehicle. The Trailer Lighting Control Module responds by applying voltage to the appropriate control circuits for the requested lamps to illuminate the lamps on the attached trailer. The Trailer Lighting Control Module constantly monitors the trailer’s reverse (optional), park, and left and right stop/turn signal lamps.

Vehicles equipped with a Trailer Lighting Control Module cannot drive as much current on each circuit when compared to the non-Trailer Lighting Control Module trailer lighting system. The Trailer Lighting Control Module drives four trailer circuits using four solid state drivers that are fed from two 30A lighting fuses. If the total current on the circuits overloads either of the fuses, it will fail. If any single lighting circuit exceeds the driver threshold, it will deactivate the output for the balance of the key cycle and a reactivation of the lamp load is required. Individual DTCs are activated for each circuit and that load is turned off due to high current. If a trailer draws too much current, it may be helpful to change some or all of the trailer lighting to LEDs.

Beginning with the 2020 model year, the trailer park lamps amperage capability was increased to handle electrical loads up to 16 amps. The park lamp circuit was moved from terminal 5 to terminal 25 and driven by an internal relay that allows for higher amperage values for the parking lamps. The park lamp circuits are not used for trailer connection detection on 2020 models.

For additional trailering lighting information, refer to #PIT5747A and Bulletin #20-NA-198.

Trailer Tire Pressure Monitoring System

The Trailer Tire Pressure Monitor System is designed to monitor the pressure of the trailer tires and warn the driver when a low-pressure condition exists. Trailer Tire Pressure Monitor System sensors for four tires are provided in the vehicle’s glove box. The system can accommodate a trailer with up to six tires if additional sensors are purchased from the dealership. Also, the system can be paired with up to five individual trailers. The sensors must be mounted onto each tire and wheel assembly, and the sensors must be learned by the vehicle by following the learning procedure in the appropriate Service Information.

The Trailer Tire Pressure Monitor System sensors monitor the air pressure in the trailer tires and transmit the trailer tire pressure readings to a receiver located in the vehicle. The tire pressure values can be viewed in the trailering app on the vehicle’s infotainment screen. (Fig. 2)

Fig. 2

Fig. 2

TIP: The sensor readings can only be received from a trailer that has axles no more than 23 feet (7 meters) from the rear of the truck. For example, if the first axle of a trailer is less than 23 feet, yet the second or third axle is farther, the system can only receive data from the first axle. (Fig. 3) GM does not offer a system to extend the range.

Fig. 3

Fig. 3

The system is compatible with trailer tires that have placard pressure values from 15 – 100 psi (103 – 689 kpa). The system can handle higher pressures, but any pressures higher than 100 psi will not be displayed. The hole in the wheel for the tire stem must be 0.453 inches (11.43 mm) in diameter. Use of the pressure sensors on a wheel with a different stem hole size could result in loss of air from the tire.

In addition, the system monitors the temperature of the trailer tires. If the system detects a high temperature on one or more of the trailer tires, a warning message will be displayed on the DIC. Common causes for high trailer tire temperature are underinflation, overloading, or tire damage.

Trailer Tire Pressure Monitoring Diagnosis

The learn procedure for the trailer tires requires using the EL-46079 Tire Pressure Monitor Diagnostic Tool or EL-50448 Tire Pressure Monitor Sensor Activation Tool, just as when learning the tire pressure sensors on a vehicle. If the trailer is not available, the trailer tire pressure sensors can be learned using the EL-52641 Trailer Presence Simulator Tester, which can simulate the presence of a trailer. (Fig. 4) The tool can be helpful when a customer would like the trailer tire pressure sensors learned without having the actual trailer at the dealership.

Fig. 4

Fig. 4

When using the tire pressure monitor special tool to activate a sensor, ensure the tool is placed along the tire sidewall close to the sensor and not on the rim. If a sensor is not recognized, it may help to rotate the wheel so that the sensor is in a different position relative to the trailer. The sensor activation procedure may have to be repeated up to three times before determining a sensor is malfunctioning. If a particular sensor is not learned and the horn does not chirp, it may be necessary to rotate the wheel to a different position due to the RF signal being blocked by another component.

A sensor also may have been damaged by a previous wheel/tire service or flat tire event. Occasionally sensor transmissions are not received by the control module due to radio interference from internal sources, such as aftermarket ignition systems, DVD players, CB radios, etc., or external sources.

Before replacing a sensor, perform the learn procedure for all sensors to make sure the DTC was set for the correct position on the trailer. The wheels may have been exchanged during a previous tire rotation without learning the new positions. In addition, the use of tire sealants, other than those approved by GM, can obstruct the sensor pressure sensing port and cause inaccurate tire pressure readings. If this condition is verified, remove the sealer from the tire and replace the sensor.

A sensor low battery condition also will set a sensor DTC but will not display a message on the Driver Information Center. The sensor battery condition can be verified in the scan tool BCM data list. If a sensor low battery condition is indicated on the scan tool, the sensor will need to be replaced.

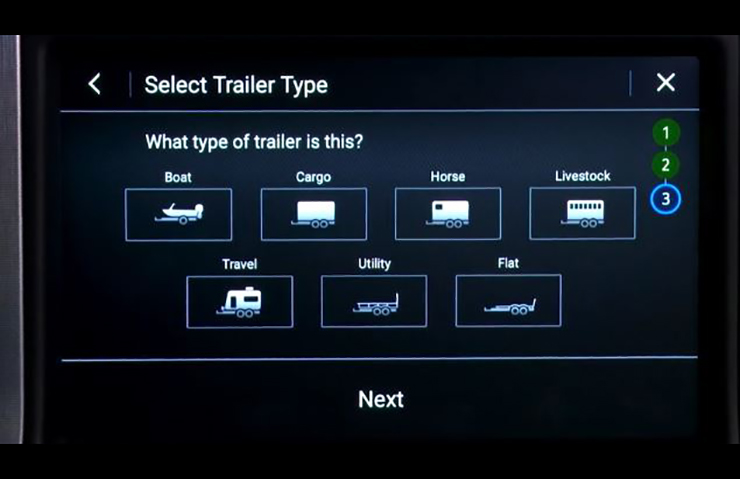

Trailering App Profiles

When a trailer is connected, the driver has the option of selecting a Guest profile or naming the trailer and storing settings in the trailering app. The settings can include basic information — profile name, hitch type and trailer type — or more advanced information — Tow/Haul Mode reminder, Trailer Tire Pressure, and maintenance reminders. (Fig. 5)

Fig. 5

Fig. 5

If the trailering app is set up incorrectly for the connected trailer, several DTCs or Driver Information Center messages may appear. For example, if a trailer does not have any reverse circuit loads, yet a reverse circuit load is expected in the trailering app, the Trailer Lighting Control Module will set DTC B3890 (Trailer Backup Lamps Circuit). If the trailer does not have reverse lamps or any loads on the reverse circuit, change the trailering app profile settings and clear any DTCs. Do not replace the Trailering Lighting Control Module.

For a list of possible trailering app-related message that may appear on the Driver Information Center, refer to the Trailering Description and Operation document in the appropriate Service Information.

– Thanks to Kevin Minor