Several DTCs may be set on some 2024 Trax models equipped with the 1.2L engine (RPO LIH) that may be caused by debris in the oil pump or an engine wiring harness condition.

If DTCs P0521 (Engine Oil Pressure Sensor Performance) and/or P06DD (Engine Oil Pressure Control Solenoid Valve Stuck Off) or P06DE (Engine Oil Pressure Control Solenoid Valve Stuck On) are set, first check the engine oil level and address any drivability concerns.

Wiring Harness

If there are not any drivability concerns and the oil level is correct, remove the engine oil pressure control solenoid valve and inspect for proper terminal tensions, crimps and locks.

Next, test for 10 to 30 Ohms between control terminal 2/B and ignition terminal 1/A of the engine oil pressure control solenoid valve.

If the test results are within range, inspect the solenoid valve for any signs of debris. If no debris is found and the concern is not isolated to the engine oil pressure control solenoid valve, remove the intake manifold to access the engine oil pressure sensor. Disconnect the engine oil pressure sensor and test for less than 10 Ohms between low reference circuit 580 terminal 2 and ECM connector X1 terminal 23.

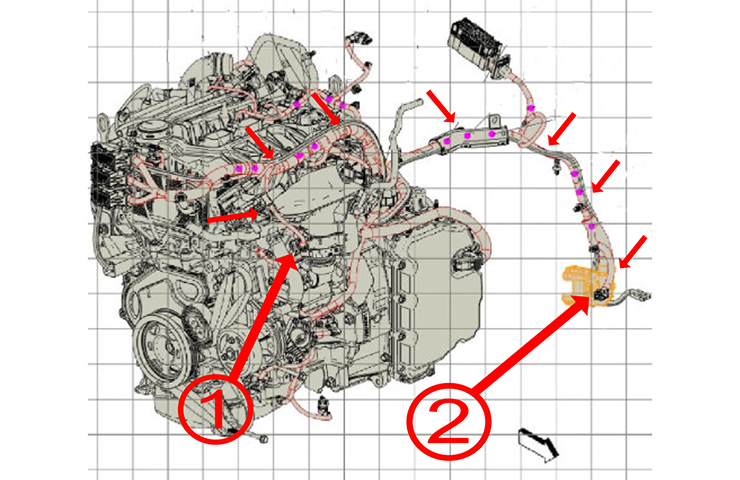

If the resistance is within range, manipulate the engine wiring harness between the oil pressure sensor (Fig. 3, #1) and connector X125 (Fig. 3, #2) and look for a change in the resistance reading. If the concern is not isolated to the engine wiring harness, reinstall all components.

Fig. 3

Fig. 3

Oil Pump

If the concern is not addressed by repairs to the engine wiring harness, it will be necessary to perform the engine oil pump screening test. The purpose of the procedure is to complete two tests of ten cycles each, or to trigger DTCs P0521, P06DD or P06DE, whichever comes first. The test should be stopped immediately upon triggering a listed DTC.

Refer to #PIP5932 for the complete testing procedure. During the test, engine speed will be raised for several short periods of time, followed by idling the engine. The test cycle should be performed ten times.

If any of the DTCs set during the first set of 10 cycles, refer to Engine Oil Pump Replacement in the appropriate Service Information.

If any of the DTCs are not present, turn off the engine, disconnect the scan tool and allow the modules to power down. Next, reconnect GDS2 and repeat the test cycle ten more times, again checking for DTCs P0521, P06DD and P06DE.

If the DTCs set during the second set of test cycles, refer to Engine Oil Pump Replacement in SI. If the DTCs do not set, no further action is required.

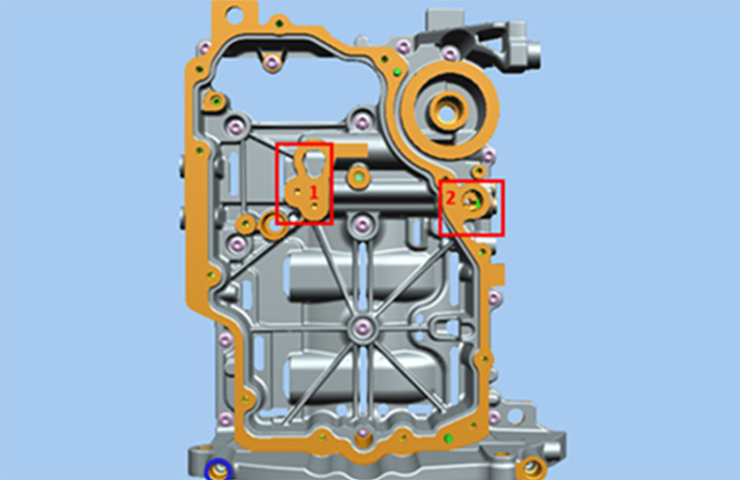

TIP: If oil pump replacement is needed, ensure the three oil pump oil holes (Fig. 4, Area 1) and OCV mounting hole (Fig. 4, Area 2) are free of debris before installing the oil pump and OCV. When installing the engine oil pan on the 1.2L engine, be sure to follow the RTV sealant instructions in #PIP5739 to ensure proper oil pan installation.

Fig. 4

Fig. 4

For additional information, refer to #PIP5932.

– Thanks to Raymond Haglund