A growling, knocking or rhythmic thumping sound may be heard on some 4.3L engines (RPO LV3), 5.3L engines (RPO L82, L84) and 6.2L engines (RPO L87, LT1, LT2, LT4, L8T) on some 2019-2024 Camaro, Corvette, Silverado 1500, Sierra 1500; 2020-2024 Silverado 2500/3500, Sierra 2500/3500; 2021-2024 Tahoe, Suburban, Yukon, Escalade; 2021-2024 Express, Savana; and 2022-2024 CT5 models. The engine may be hard to rotate once at operating temperature, which may lead to it locking up and unable to restart. Once the engine cools down to ambient temperature, it may refire and run normally. In addition, the starter fuse may be open. All of these conditions may be a sign of an early bearing failure.

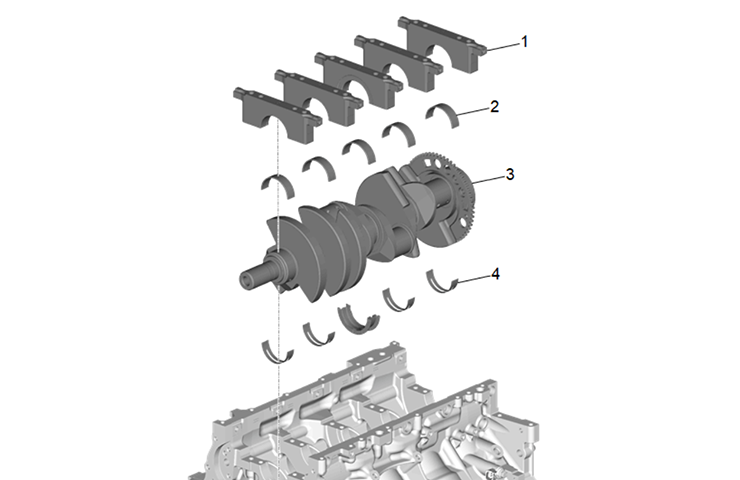

If these engine conditions are present, check for crankshaft bearing failure or a damaged thrust bearing. (Fig. 8) There are several items to inspect to determine if bearing failure has occurred.

Fig. 8

Fig. 8

Engine Oil and Filter

Begin diagnosis by inspecting the engine oil and filter for bearing material or excessive metal debris. (Fig. 9) Pouring the oil through a white shop towel may be helpful.

Fig. 9

Fig. 9

TIP: There may be light glitter in the oil from the manufacturing process if the engine has not had its first oil change. In this case, further engine inspection is necessary.

Remove the engine oil pan for further inspection of the crankshaft rod and main bearings if bearing debris has been identified.

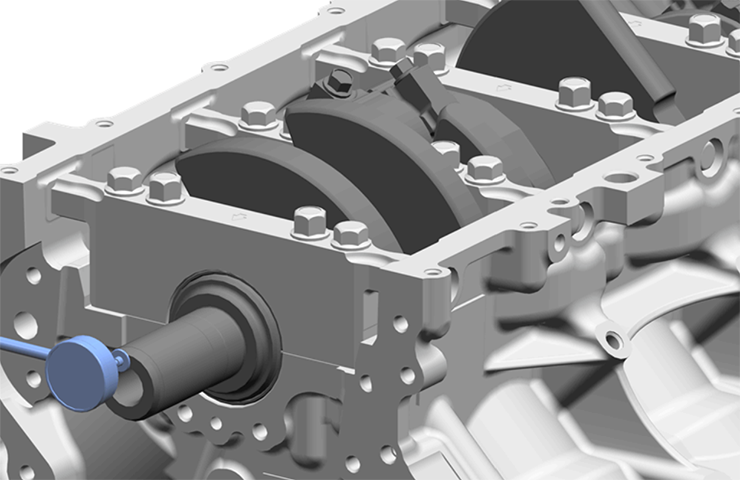

In addition, if material is found in the engine oil, measure crankshaft end play following the appropriate Service Information. (Fig. 10) If there is not excessive crankshaft end play, remove the engine accessory drive belt and run the engine again. If the noise is eliminated, check the accessory drive belt-driven components for possible issues.

Fig. 10

Fig. 10

Engine Noise

With the engine at a warm idle, increase engine speed to 1,500 – 1,800 RPM and then back to idle. Listen for the intensity of the noise to increase under higher engine speeds.

The use of a stethoscope or PicoScope also may help verify if the noise is in the bellhousing or rear of the transmission instead of the engine.

Many evaluations have indicated that the noise is eliminated when the transmission is disconnected. However, do not try to isolate the noise by backing off the torque converter from the engine and running the engine, which may cause engine or transmission damage. Replacing the transmission will not resolve the noise condition.

TIP: If crankshaft bearing damage is found once all diagnostic procedures are completed, refer to Bulletins #22-NA-074 and #18-NA-073 for additional repair directions.

Starter Concerns

If the starter fuse is blown, replace the starter fuse once the new engine is installed. Do not replace the starter assembly. If there are any other starter concerns after fuse replacement, check the appropriate Service Information for additional diagnostic procedures to perform.

For more information on possible bearing failure, refer to the latest version of Bulletin #23-NA-170.

– Thanks to Bryan Salisbury