Some 2011-2019 Silverado 2500/3500 and Sierra 2500/3500 models may have a shudder, bounce or bucking condition from the rear of the truck while braking when towing a gooseneck (Fig. 2) or 5th-wheel trailer. The brake shudder is found on vehicles with gross combined weights usually exceeding 20,000 lbs. No DTCs are stored that are related to the Trailer Brake System or Electronic Brake Control Module (EBCM).

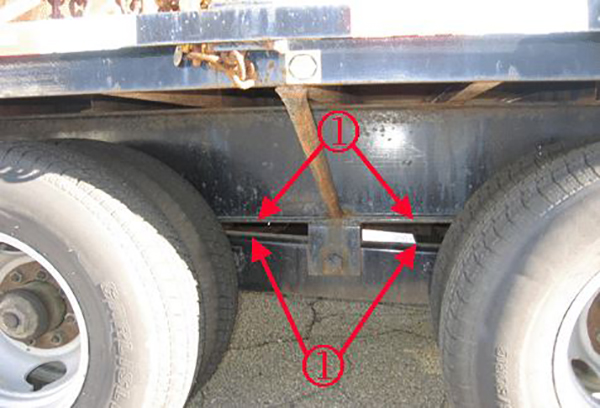

Fig. 2

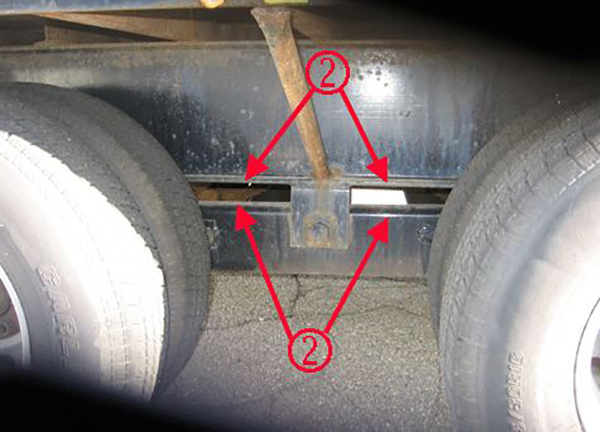

Fig. 2

Heavy gooseneck and 5th-wheel trailers have the ability to impose a dynamic pulsing force on the tow vehicle when driving on smooth roads. The pulsing force acts in a forward and reverse direction on the tow vehicle at a rate of 3 to 5 times per second and can be subtle to the driver. As the combination decelerates, the trailer induced pulsing force is still present and, while braking, the driver may unintentionally begin to fluctuate the force on the brake pedal in response to the trailer’s pulsing input force. As the brake pedal force fluctuates, the resulting alternating deceleration forces that the truck produces magnifies the trailer impulse forces, resulting in the shudder condition.

The following tips may help verify the issue and minimize its potential to occur. Trailer, trailer loading, and trailer hitch characteristics will influence the magnitude of a trailer’s pulse force.

Truck and Trailer Weight

Measure the actual truck and trailer weights, with the trailer loaded to the point that exhibits the condition. If any weight parameter is exceeded, such as the Front Gross Axle Weight Rating (FGAWR), Rear Gross Axle Weight Rating (RGAWR), Gross Vehicle Weight Rating (GVWR) or Gross Combined Weight Rating (GCWR), the load must be reduced before investigating further.

The trailer’s tongue weight must be within the range of 15% to 30% of total trailer weight not exceeding the truck’s Rear Axle Gross Weight Rating, Gross Vehicle Weight Rating or Gross Combined Weight Rating. The trailer must not exceed its weight ratings and trailer cargo must be properly secured.

Hitch Stiffness

Play and lack of stiffness between the truck and trailer’s hitch components will affect the trailer-induced pulse forces. Gooseneck ball and 5th-wheel kingpin sizes and load ratings must be correct for the trailer weight used. Trailer gooseneck extension set screws must be at the manufacturers specified torque value. Gooseneck ball and coupler parts showing indication of wear should be replaced and 5th-wheel pivot assemblies must be functioning as intended.

Hitch Movement

Observe the trailer hitch and trailer tongue during acceleration and deceleration events. If excessive movement is noted, a different style/brand of hitch may be required focusing on the weight rating and base structure. A hitch structure with a wider base that is mounted to the provisions on the frame for the 5th-wheel hitch is recommended. Also verify the load rating of the installed hitch.

Level Trailer Height

The trailer should be level from front to rear when connected to the truck. (Fig. 3) Height difference between the front and rear of the trailer may contribute to the magnitude of pulsing force the trailer can produce. Trailers that have a tandem axle assembly using a load equalizer beam, as a component in the trailer’s suspension, can produce more pulsing force when the front of the trailer is higher than the rear of trailer. (Fig. 4)

Fig. 3

Fig. 3

Fig. 4

Fig. 4

Trailer Capabilities

The trailer’s tires must be properly inflated and the trailer’s suspension must be functioning as intended. The trailer’s mechanical system performance also should be inspected and any deficiencies corrected.

Trailer Design

Trailers that place cargo closer to ground level, and trailers that have longer distances between the trailer tongue and trailer axles, will reduce the trailer’s forward and reverse pulse forces.

Brake Apply Technique

Stabilizing the driver’s brake apply foot with the heel on the floor while braking will increase the driver’s resistance to unintended fluctuation of the brake pedal in response to trailer pulse forces.

Trailer Brake Evaluation

Verify the trailer’s braking ability when the trailer is loaded to the weight where the condition is exhibited.

The trailer’s braking system should have equal or greater capability to stop the truck/trailer combination when compared to the truck’s service brake. From speeds of 20 to 25 mph (32-40 km/h) on level paved roads free from traffic, perform a full manual apply of the trailer brake controller, with the controller set to maximum gain, and no apply of the truck’s service brake. Compare deceleration to the truck’s capability for stopping the combination from the same speed on paved roads during an aggressive brake pedal apply with the brake controller set to minimum gain.

If the trailer brake capability is adequate, adjust the brake controller according to the Trailer Gain Adjustment Procedure in the Owner’s Manual and evaluate the truck and trailer combination for braking shudder again.

If the trailer brakes are not adequate, the trailer or trailer brake apply system may have an electrical malfunction, mechanical malfunction, incorrect trailer brake components, or incorrect trailer axle size that requires repair.

– Thanks to Scott Fibranz