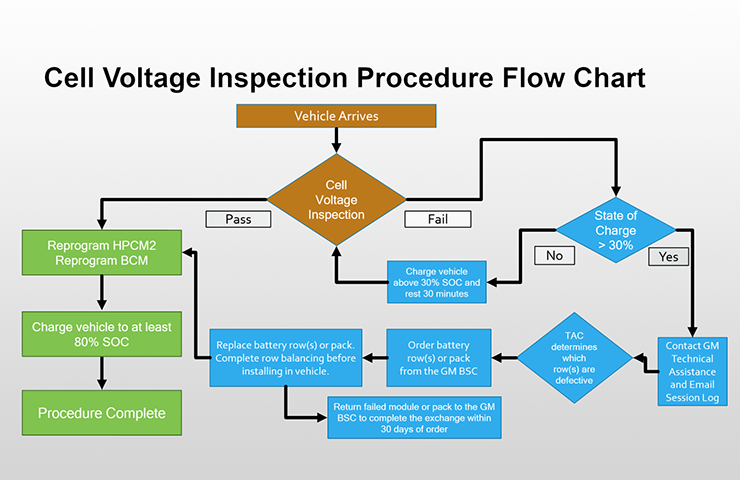

Updated battery inspection and reprogramming procedures for some 2017-2021 Bolt EV models have been released to help determine battery cell voltage performance. (Fig. 1) The repair procedure also includes reprogramming for two control modules to add new battery cell diagnostics that provide early detection of a battery cell defect. 2022 Bolt EV, Bolt EUV, and later models will have the new battery diagnostics installed at the factory.

Fig. 1

Fig. 1

The updated inspection process enables technicians to properly evaluate the battery for defective cells and replace battery rows as needed. (Fig. 2)

Fig. 2

Fig. 2

Battery Cell Voltage Inspection

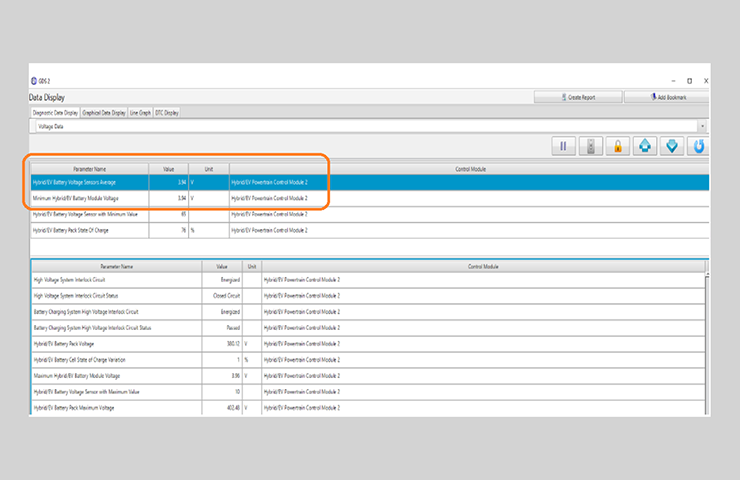

Begin the battery cell voltage inspection by using GDS2 to navigate to the Hybrid/EV Powertrain Control Module 2 (HPCM2) Voltage Data screen, which shows the average battery cell voltage and the minimum cell voltage parameters. (Fig. 3) To determine if the battery passes the inspection, subtract these two values. If the difference is equal to or less than 0.08 volts, the vehicle passes inspection, which allows proceeding to the green path on the inspection flow chart.

Fig. 3

Fig. 3

If the difference between the average battery cell voltage and the minimum cell voltage parameters is more than 0.08 volts, then the blue path on the inspection flow chart should be followed. Creating a GM TAC case is only required when indicated on the flow chart.

Control Module Reprogramming

Once a battery has passed inspection or the necessary battery row(s) or pack have been replaced, the HPCM2 and the Body Control Module (BCM) should be reprogrammed. Both warranty claim codes for programming will be required for the warranty claim. After reprogramming, charge the vehicle above 80% state of charge.

The new calibration installed during reprogramming includes two new diagnostics:

- Sustained cell delta voltage monitor

- Intermittent cell delta voltage monitor

Existing DTCs are being repurposed for the sustained cell delta voltage monitor, with one DTC for each of the 96 cell groups. A new DTC, P0BBD, is being added to the Bolt EV for the intermittent cell delta voltage monitor. These diagnostics run in the HPCM2 module. If either of these two new diagnostics set, the vehicle will stop charging and not be allowed to start on the next key cycle. Refer to the appropriate Service Information for details on how to diagnose these new DTCs.

The new module calibrations also allow for the use of a mixture of N2.1 and N2.2 cell chemistry battery sections in 2017-2019 Bolt EVs. With this change, a new N2.2 battery section (row) may now be used to service these older vehicles. The EV range will not increase with the use of the newer chemistry. Range is limited by the lowest capacity cell in the pack.

Parts Information

If the vehicle fails inspection and a battery section (row) needs to be replaced, the new battery sections will arrive custom-balanced, but must have a short, final balancing completed once installed into the battery pack. It will be faster to balance the replacement section if the state of charge displayed in green bars on the instrument cluster is less than 100% at the time of ordering. Battery sections cannot be ordered above 4.0v average cell voltage. Use software revision 10 or newer for the EL-50332-B EV/HEV Battery Service and Depowering Tool.

Once the section order has been placed, the vehicle should not be released to the customer, charged, or driven more than a half mile (0.8 km). Follow Bulletin #18-NA-236 to order the battery. Ancillary parts such as thermal pads, heat sinks, and coolant can be ordered through the normal part ordering process.

Most battery orders will take five days to complete. The new section (row) will be custom charged to your specification to save time during installation. A quick final pack balance is needed using the EL-50332-B tool, which should take only minutes with the pre-balance already complete. The final balance is critical for maximizing EV range for the customer. A copy of the repair order and the failed section must be returned to the GM Battery Service Center. Refer to Bulletin #18-NA-236 on how to return failed batteries.

During the battery cell diagnosis, most vehicles will pass the battery cell voltage inspection, requiring only the control module reprogramming. Use the appropriate labor codes in the field action bulletin to account for the different diagnostic pathways and the time involved to repair.

For additional information on battery cell inspection and reprogramming, check out the June 2021 Emerging Issues seminar.

– Thanks to Lane Rezek

Check out the cell balancing video in the Propulsion segment of the August 2020 Emerging Issues seminar.

WOULD LOVE TO SEE SERVICE INFORMATION ACTUALLY INCLUDE BETTER GRAPHICS FOR EACH INDIVIDUAL SECTION BALANCE PRODECURES ETC. OR VIDEOS OF WHERE & HOW. SEEING THIS IN ACTUAL PICTURES OR ACTION WOULD BE LESS CONFUSING THEN READING THE WAY IT’S OUTLINED IN S.I.